Comprehensive Metal Services.

Comprehensive Metal Services.

Metal Finishing

Anodizing, plating, coating, and surface treatments from Nadcap-certified facilities.

- Anodizing (Type I, II, III)

- Cadmium & Zinc Plating

- Powder Coating

- Chemical Film/Alodine

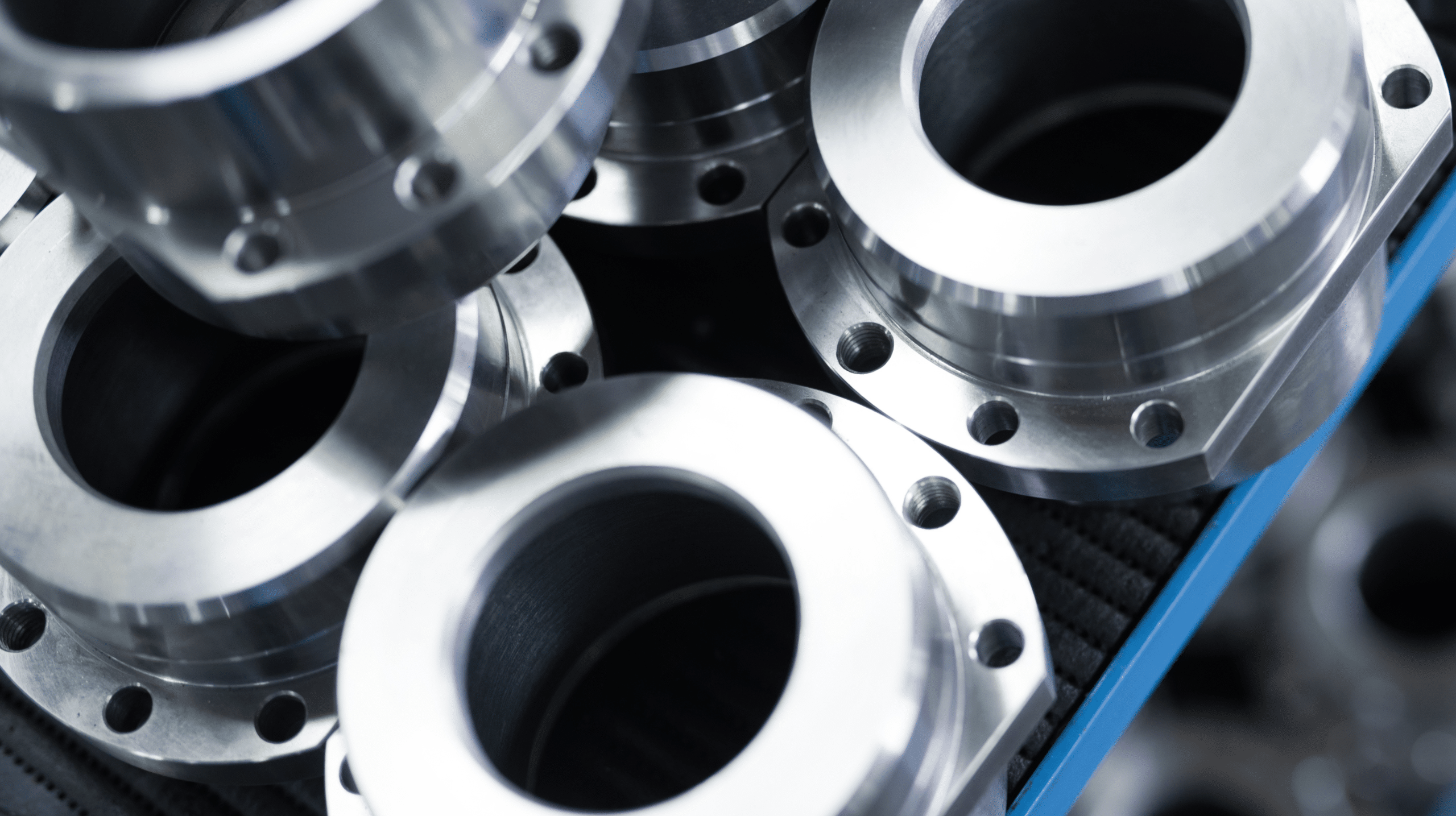

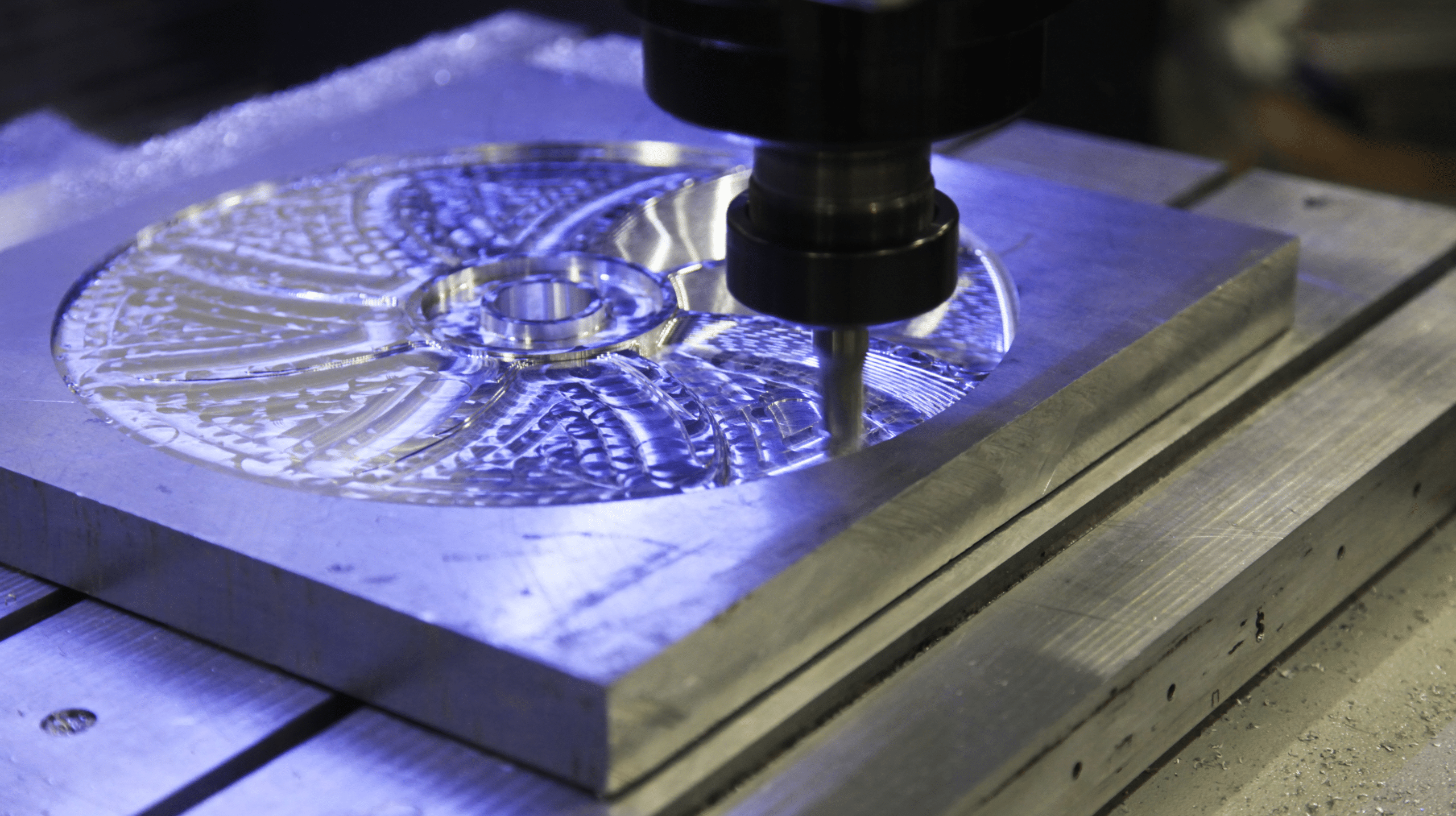

CNC Machining

Precision milling and turning from prototype to production. State-of-the-art equipment with fast, accurate results.

- CNC Milling

- CNC Turning

- Multi-Axis Machining

- Prototype Development

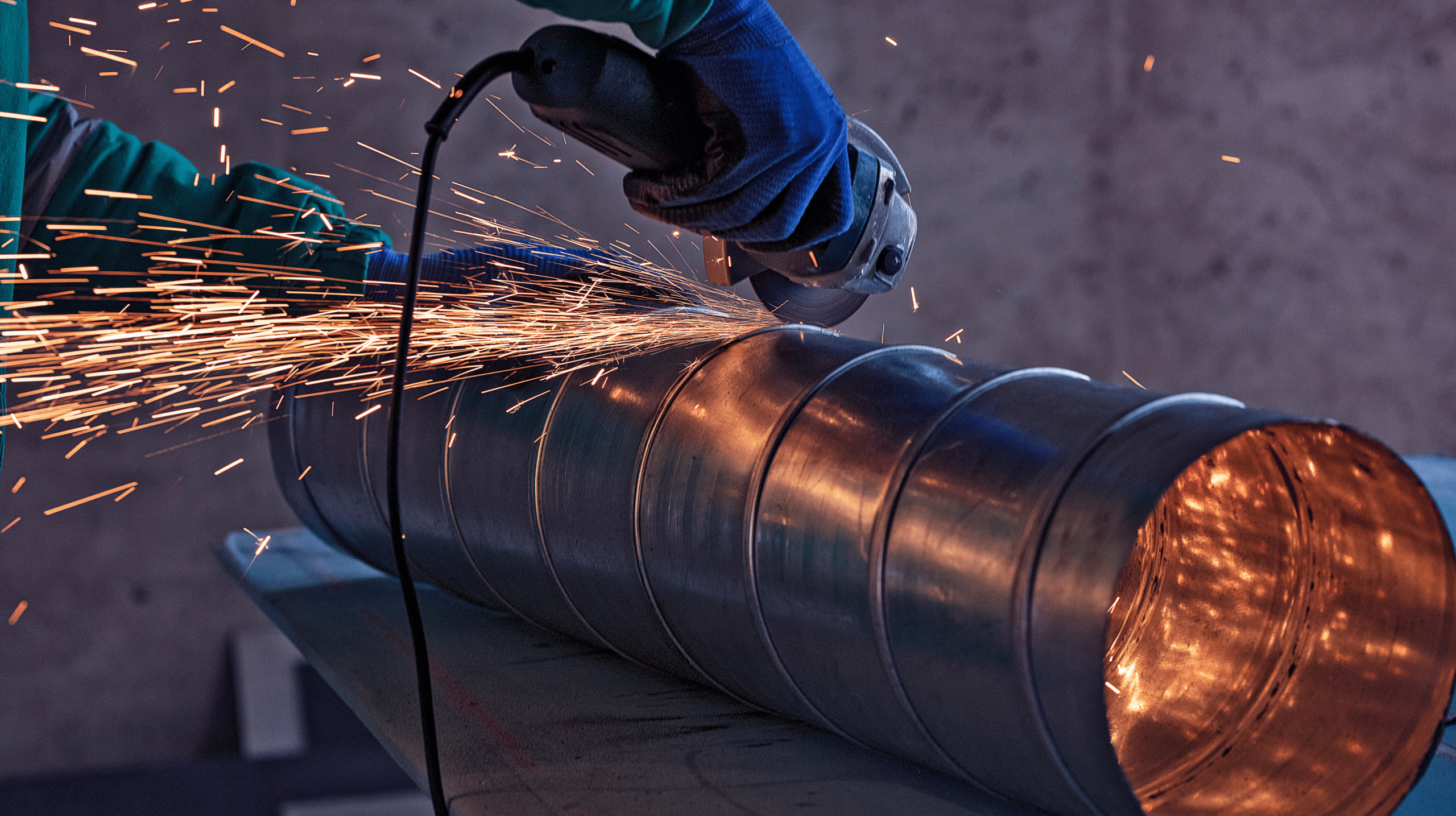

Metal Fabrication

- Sheet Metal Fabrication

- Welding & Assembly

- Laser Cutting

- Custom Enclosures

Metal Sales & Processing

Strategic inventory of aerospace and commercial-grade metals with precision processing capabilities. From aluminum to titanium, cut and processed to your specifications.

- Aluminum, Stainless, Titanium, Carbon Steel

- Precision Sawing & Shearing

- Slitting & Cut-to-Length

- CNC & Near-Net Shape Cutting

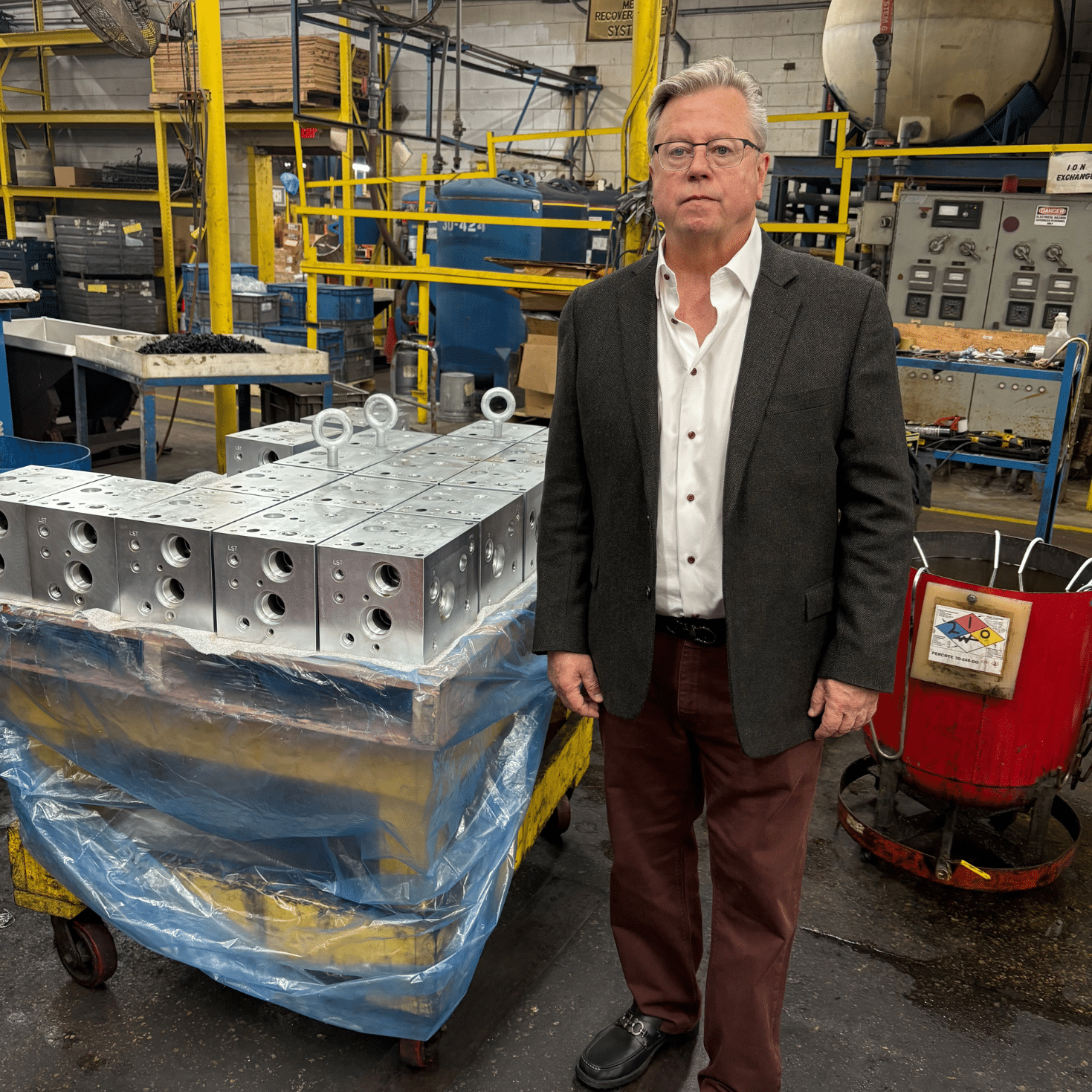

One Partner. Every Process. Seamless Coordination.

Certified Quality

Complete Solutions

Fast Turnaround

Expert Consultation

Trusted Across Critical Industries

Aerospace & Aviation

Defense & Military

Medical Devices

Electronics & Telecommunications

Automotive

Industrial Equipment

Food & Beverage Equipment

Energy & Power Generation

Not Sure Which Process You Need?

Common Selection Scenarios:

Need corrosion resistance?

Anodizing (aluminum), Zinc Plating (steel), Passivation (stainless)

Need wear resistance?

Hardcoat Anodizing, Electroless Nickel, Black Oxide

Need decorative finish?

Bright Dip Anodizing, Powder Coating, Architectural Anodizing

Need electrical conductivity?

Tin Plating, Silver Plating, Copper Plating

Meeting Your Industry's Standards .

ISO 9001:2015

Quality Management

Nadcap Accreditation

Aerospace/Defense Excellence

AS9100

Aerospace Quality

ITAR Compliance

Defense Compliance

Mil-Spec Compliance

Military Standards

FDA Compliant Partners

Medical Devices

FAQs

Can you handle multi-process projects (materials + machining + finishing)?

Absolutely. This is one of our key advantages. You can source materials, have them machined, finished, and assembled—all coordinated through Aerospace Metals. Single quote request, single point of contact, seamless project management.

What certifications do your partners have?

Every partner maintains ISO 9001:2015 certification minimum. For aerospace and defense projects, we work with Nadcap-accredited and AS9100-certified facilities. ITAR-registered partners available for defense projects.

What are typical lead times?

Lead times vary by service. Material processing: 1-2 weeks. Standard finishing: 2 weeks. Machining: 2-3 weeks depending on complexity. We offer expedited service for urgent needs. Contact us with your specific requirements for accurate timing.

What materials can you work with?

We maintain inventory of aluminum alloys, stainless steel, carbon steel, titanium, copper, brass, and specialty alloys. Our partners can machine and finish virtually any metal. Specific capabilities depend on the process—contact us to discuss your material.

What's the minimum order quantity?

We handle everything from prototypes (single pieces, small material cuts) to high-volume production runs. There's no strict minimum—we'll find a solution suited to your volume.

How do I request a quote?

Use our online quote form, email your specifications and drawings, or call us directly. For material orders, specify alloy, dimensions, quantity, and any processing needed. We typically respond within 24 hours with a detailed quote.

Can you meet Mil-Spec requirements?

Yes. Our partners are experienced with military specifications including MIL-A-8625 (anodizing), MIL-DTL-5541 (chemical film), and many others. Materials can be supplied with full mill certifications and traceability. Specify your Mil-Spec requirements when requesting a quote.

- Get started

Let’s Work Together

Send us message to get more detailed info or to request a phone call.