Comprehensive Plating Services.

- Quick Specifications

Processes

Zinc, Nickel, Chrome, Copper, Tin, Specialty

Certifications

ISO 9001:2015, Nadcap (aerospace)

Lead Times

10-14 days standard, rush available

Industries

Aerospace, Defense, Automotive, Medical

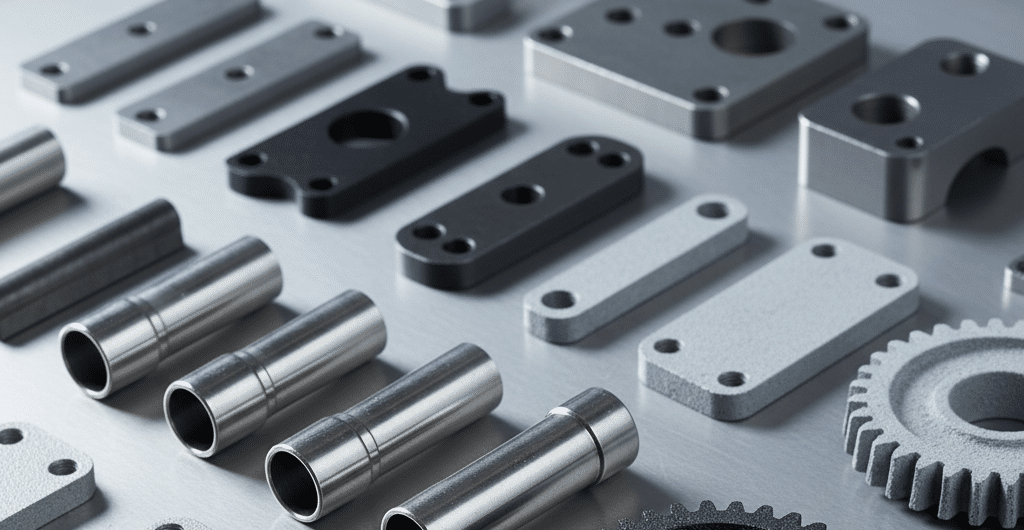

Electrochemical Surface Enhancement

Metal plating is an electrochemical or chemical process that deposits a thin layer of metal onto a substrate to enhance corrosion resistance, improve conductivity, increase durability, provide wear resistance, or achieve specific aesthetic appearances.

At Aerospace Metals, we coordinate a comprehensive range of plating services through our certified partner network. Every facility maintains ISO 9001:2015 certification minimum, with Nadcap-accredited partners available for aerospace and defense critical applications.

- Corrosion resistance

- Wear resistance

- Complex geometries

- Improved conductivity

- Aesthetic finishes

- Tight tolerances

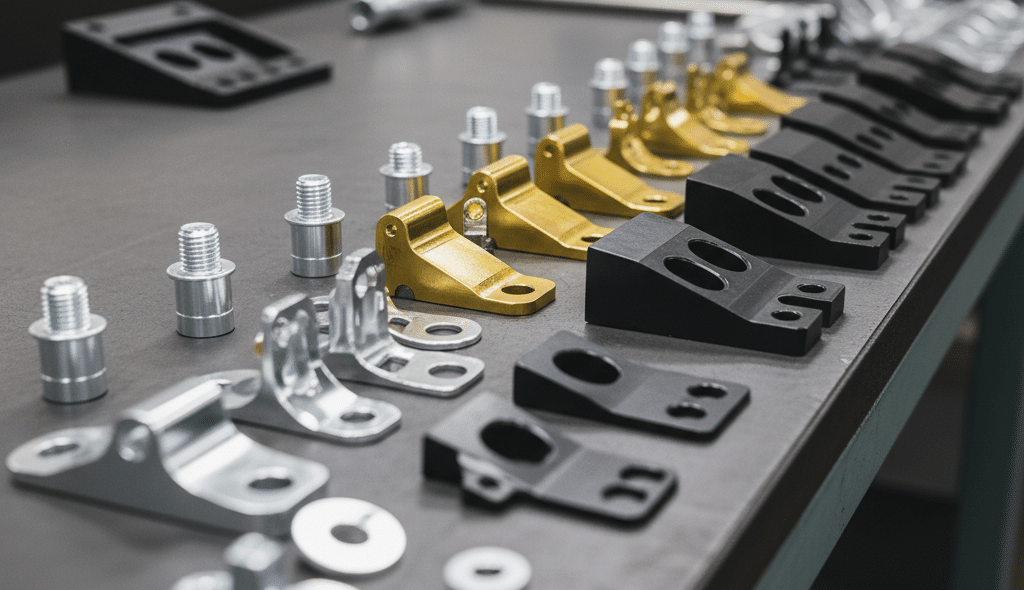

Our Plating Capabilities

Zinc & Zinc-Alloy Plating

Zinc and zinc-alloy plating provides exceptional corrosion protection for steel components at cost-effective pricing.

Zinc Plating (Electroplated)

Standard zinc plating for general corrosion protection. Thickness: 0.0002" - 0.0005"

Black Zinc-Nickel Plating

Combines corrosion resistance with low-reflectivity black finish.

Zinc-Nickel Plating

Superior corrosion resistance (10-15x better). 12-15% nickel content.

Zinc-Iron Plating

Cost-effective alternative with excellent paintability and weldability.

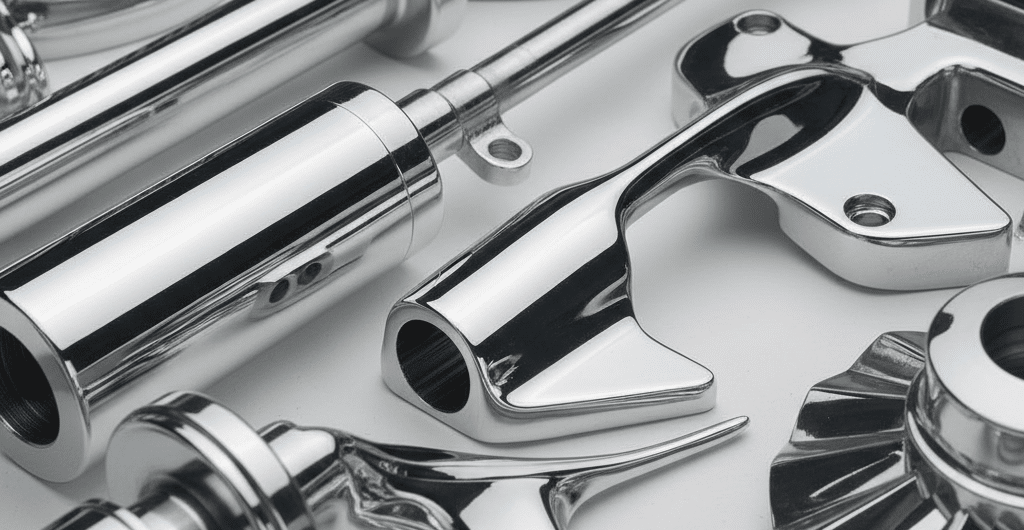

Nickel & Chrome Plating

Nickel and chrome plating provide excellent corrosion resistance, hardness, wear resistance, and aesthetic appeal.

Bright Nickel Plating

High-luster reflective finish with excellent corrosion resistance.

Hard Chrome Plating

Extremely hard surface (65-70 HRC). Exceptional wear resistance.

Black Chrome Plating

Dark finish with solar absorption properties.

Electroless Nickel Plating

Uniform thickness on complex geometries. Mid-Phos (4-9% P) or High-Phos (10-13% P).

Decorative Chrome Plating

Bright, reflective aesthetic finish over nickel undercoat.

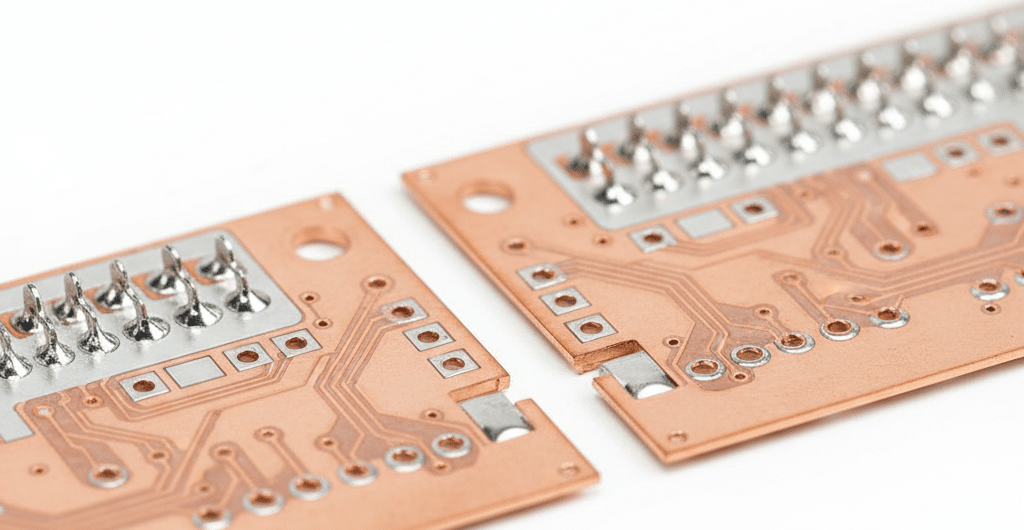

Copper & Tin Plating

Copper and tin plating provide excellent electrical conductivity, thermal conductivity, and solderability.

Copper Plating

Excellent electrical and thermal conductivity. Improves adhesion between dissimilar metals.

Tin-Lead Plating

Traditional solder-ready coating (various ratios). Note: RoHS restrictions apply.

Tin Plating

Superior solderability, food-safe. Available in Bright, Matte, or Solder-Friendly finishes.

Specialty & Functional Plating

Specialty plating for unique performance requirements, aesthetic demands, or specific industry applications.

Brass Plating

Decorative gold-like appearance without precious metal cost.

Silver Plating

Highest electrical & thermal conductivity. Excellent solderability and antimicrobial properties.

Multi-Layer Plating Systems

Copper-Nickel-Chrome, Nickel-Gold, and custom combinations.

Gold Plating

Exceptional corrosion resistance, excellent conductivity, luxury appearance.

Bronze Plating

Antique or vintage aesthetic appearance with corrosion resistance.

EMI/RFI Shielding

Copper, nickel, or silver plating for electromagnetic interference protection.

Steel & Stainless Treatments

Surface treatments specifically designed for steel and stainless steel substrates.

Zinc Phosphate Coating

Paint adhesion and corrosion protection. Pre-treatment for powder coating.

Stainless Steel Passivation

Removes free iron and enhances natural oxide layer. Standards: ASTM A967, AMS 2700.

Aluminum Conversion Coatings

Chemical film (Alodine, Chem Film) for aluminum corrosion protection.

Manganese Phosphate Coating

Excellent oil retention for wear reduction. Ideal for gears and moving parts.

Black Oxide for Steel

Black finish with minimal dimensional change (~0.000001"). Reduces glare.

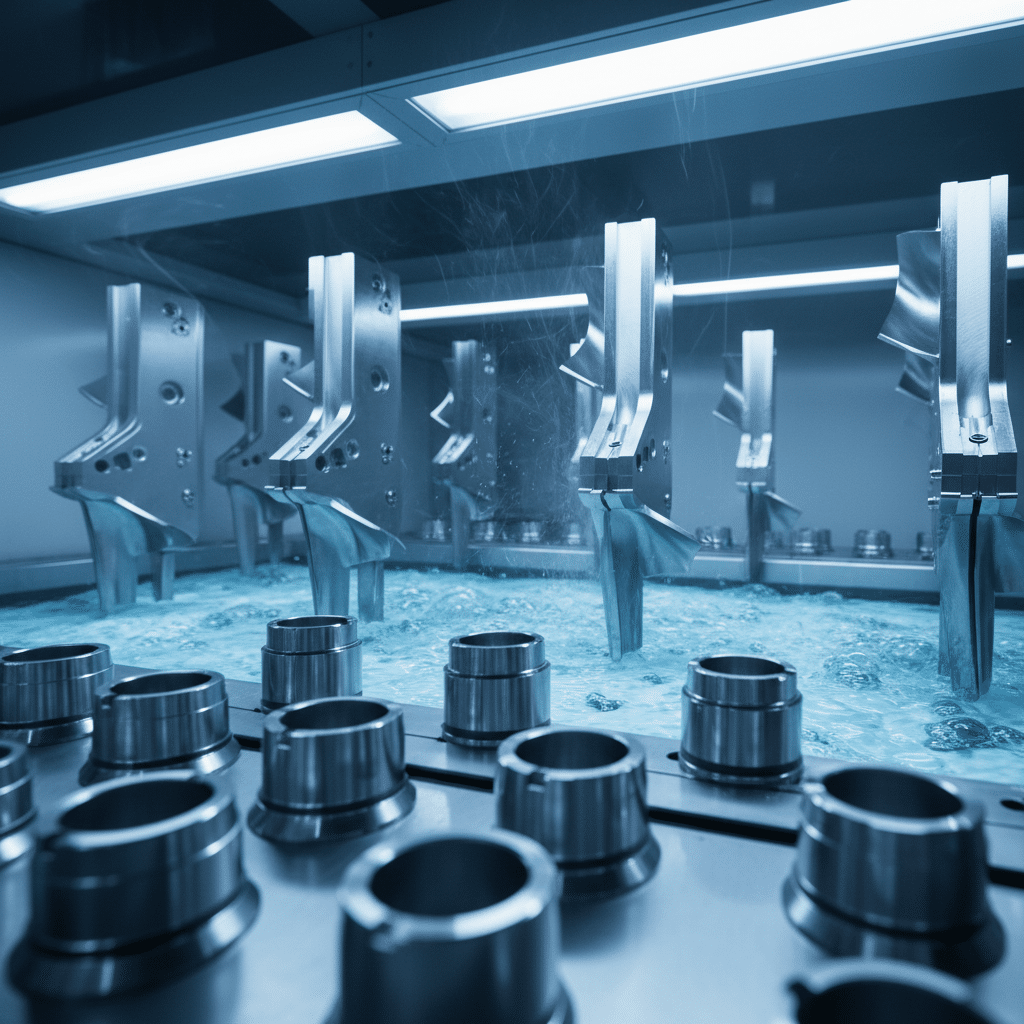

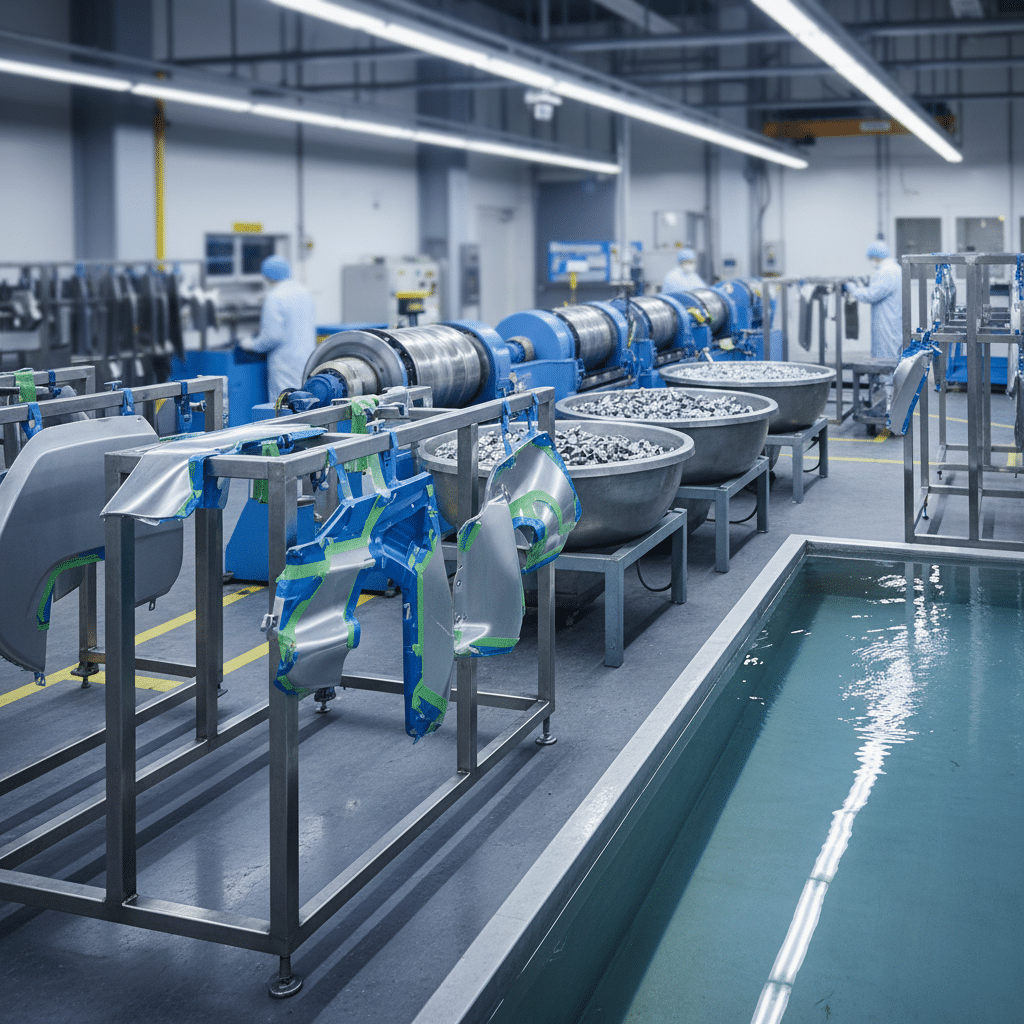

Pre-Treatment & Support Processes

Quality plating starts with proper preparation. Our partners provide comprehensive pre-treatment services and flexible processing methods.

- Pre-Treatment Services

- Alkaline & acid cleaning

- Etching & pickling

- Selective masking

- Surface activation

- Oxide removal

- Precision fixtures

- Processing Methods

Rack

Complex parts, precise control

Barrel

High-volume, cost-effective

Vibratory

Complex shapes, moderate volume

Choosing the Right Plating Process

| Performance Requirement | Best Options | Good Options |

|---|---|---|

| Corrosion Protection | Zinc-Nickel, Electroless Nickel, Cadmium | Zinc, Tin, Chrome, Nickel |

| Wear Resistance | Hard Chrome, High-Phos Electroless Nickel | Electroless Nickel, Nickel |

| Electrical Conductivity | Silver, Copper | Gold, Tin |

| Solderability | Tin, Silver | Gold, Copper |

| Cost-Effectiveness | Zinc, Black Oxide | Tin, Copper, Nickel |

Plating Solutions Across Industries

Aerospace & Aviation

- Cadmium plating for fasteners

- Zinc-nickel for high-performance hardware

- Silver plating for electrical contacts

- Hard chrome for hydraulic cylinders

Automotive

- Zinc and zinc-iron for body panels

- Decorative chrome for trim

- Black zinc-nickel for underbody

- Tin for electrical connectors

Medical Devices

- Electroless nickel for surgical instruments

- Gold plating for implants

- Passivation for stainless devices

- Silver for antimicrobial applications

Electronics & Telecommunications

- Gold plating for connectors

- Tin for solderability

- Silver for conductivity

- Nickel for EMI/RFI shielding

Industrial Equipment

- Hard chrome for wear surfaces

- Zinc for corrosion protection

- Electroless nickel for hydraulics

- Black oxide for tooling

Available Certifications Across Network

ISO 9001:2015

AS9100 Rev D

Nadcap

ITAR Registered

- Standards Compliance

- ASTM specifications

- MIL-SPEC requirements

- RoHS compliance

- ASTM specifications

- SAE standards

- REACH compliance

- Testing & Documentation

- Thickness measurement (XRF)

- Thickness measurement (XRF)

- Certificates of Conformance

- Adhesion testing

- Hydrogen embrittlement relief

- Full traceability

Expert Plating Coordination.

Comprehensive Capabilities

Access to 20+ plating processes from a single source.

Quality Assurance

ISO 9001:2015 minimum. Nadcap-accredited for aerospace/defense.

Process Expertise

Technical consultation to help select the optimal process.

Multi-Process Projects

Coordinate machining, finishing, and plating seamlessly.

Fast Turnaround

Average 10-14 days with network optimization. Rush available.

Complete Documentation

Full traceability for aerospace, medical, and defense.