Metal Painting.

- Quick Specifications

Lead Time

5-10 business days

Materials

Aluminum, Steel, Stainless Steel Magnesium Composites Zinc Die Cast

Certifications

MIL-PRF-85285

Industries

Aerospace, Defense, Automotive, Industrial Equipment, Marine

Metal Painting

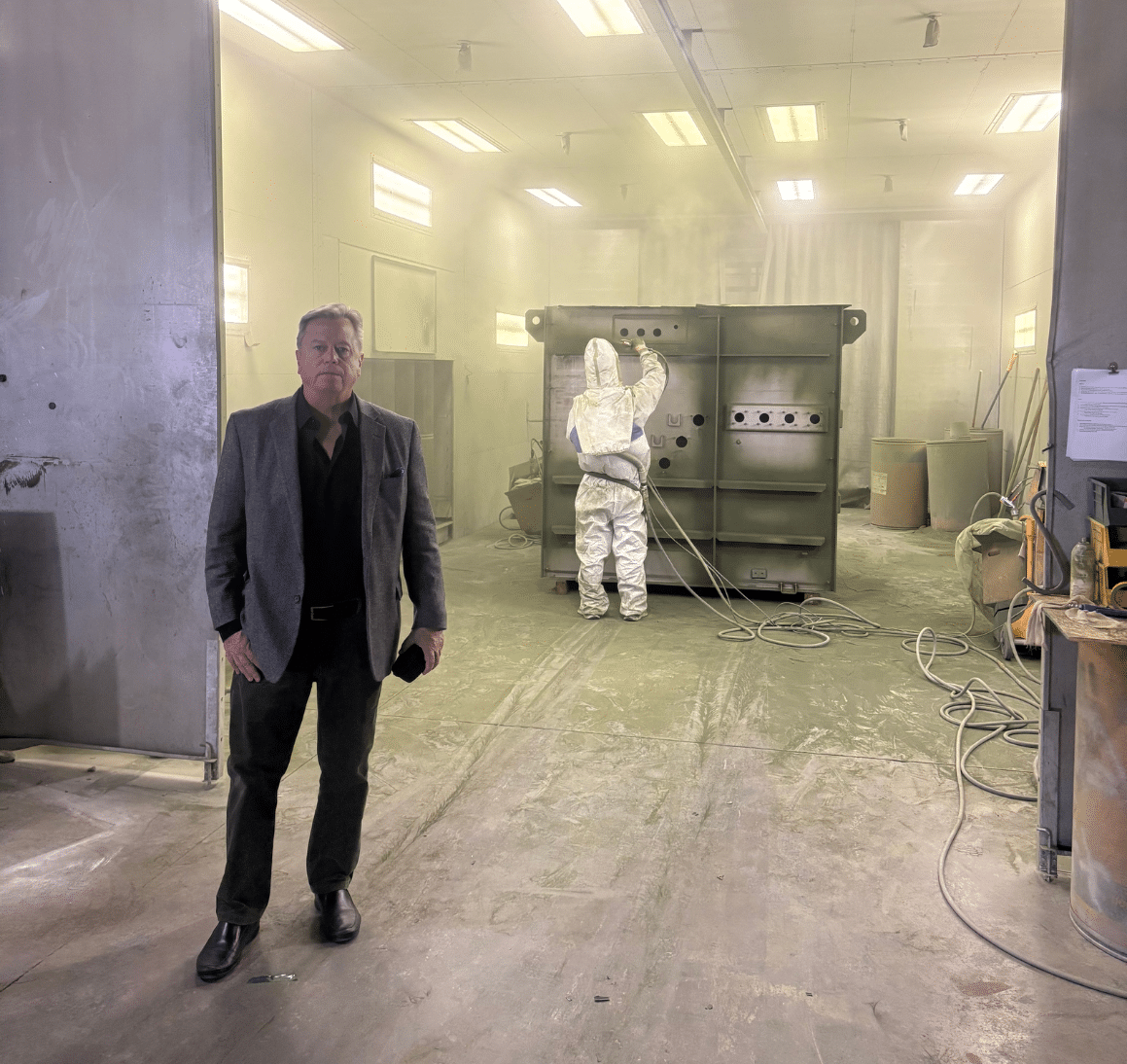

Industrial metal painting provides protective and decorative coatings using liquid paint systems. Unlike powder coating, liquid painting offers unique advantages including thinner films, greater color flexibility, and the ability to achieve specific textures and special effects.

Our partner facilities specialize in high-performance industrial painting including aerospace primers, military-spec topcoats, automotive-quality finishes, and specialty coatings for harsh environments. All painting is performed in controlled environments with proper surface preparation to ensure maximum adhesion and durability.

We coordinate primer and topcoat systems, color matching to MIL-STD-595 or custom specifications, and multi-coat systems for demanding applications. Full documentation including wet and dry film thickness measurements, adhesion testing, and material certifications is provided.

- Custom color matching

- Thin film applications

- Custom color matching

- Thin film applications

The Metal Painting Process.

Color Matching

Color specification confirmed and test panels prepared if required.

Surface Prep

Cleaning, conversion coating, and primer application as specified.

Paint Application

Spray application in controlled environment for uniform coverage.

Curing & Inspection

Proper cure cycle followed by DFT measurement and adhesion testing.

Final QC

Visual inspection, documentation, and protective packaging.

Plating Solutions Across Industries

Aerospace & Aviation

Defense

Automotive

Industrial Equipment

Technical Specifications

Compatible Materials

Aluminum

Titanium

Magnesium

Stainless Steel

Composites

Zinc Die Cast

Available Processes

Epoxy Primer

Polyurethane Topcoat

Zinc Chromate Primer

High-Temp Paint

CARC Coating

Primer & Topcoat Systems

Touch-Up Paint

Frequently Asked Questions

What's the difference between industrial painting and powder coating?

Liquid painting offers thinner films (0.5-2 mils vs 2-6 mils for powder), better color matching for small batches, ability to achieve textured and metallic effects, and suitability for heat-sensitive substrates. Powder coating excels for durability and environmental compliance.

Can you match specific colors like MIL-STD-595 or RAL?

Yes, our painting partners can match any MIL-STD-595 (Federal Standard 595), RAL, or custom color specification. For critical color matching, we recommend providing a physical sample or Pantone reference for best results.

What preparation is required before painting?

Proper surface preparation is crucial for paint adhesion. This typically includes cleaning, chemical conversion coating (for aluminum), or phosphate treatment (for steel). We coordinate the complete process including preparation steps.

What certifications are available for painted parts?

Our partners can certify to MIL-PRF-85285 (polyurethane topcoat), MIL-PRF-23377 (epoxy primer), and various other military and aerospace paint specifications. Full documentation including dry film thickness and adhesion testing is provided.