Professional Metal Finishing Services.

Complete Surface Finishing Solutions

Certified Quality

Fast Turnaround

Full Documentation

Expert Guidance

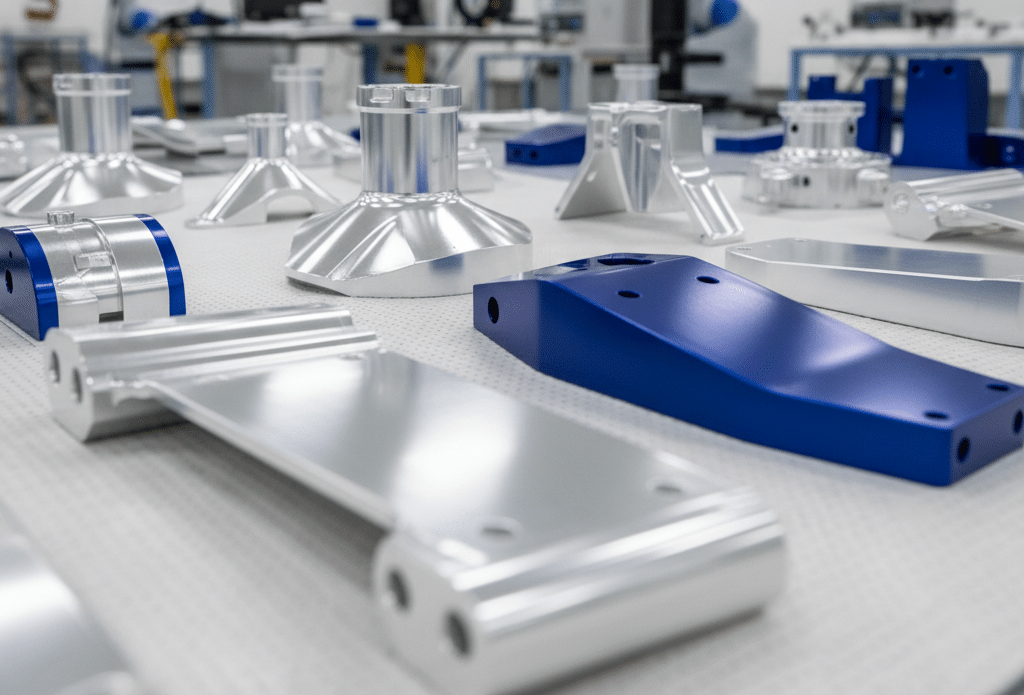

Anodizing for Aluminum

Anodizing is an electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant oxide layer. Unlike paint or plating, anodizing is part of the metal itself.

Type I - Chromic Acid Anodizing

- Excellent for tight-tolerance parts

- Superior paint adhesion base

- Common in aerospace applications

- Meets MIL-A-8625 Type I

Type II - Sulfuric Acid Anodizing (Standard)

- Available in clear or dyed colors

- Good corrosion and wear resistance

- Cost-effective for most applications

- Meets MIL-A-8625 Type II

Type III - Hardcoat Anodizing

- Exceptional wear and abrasion resistance

- Exceptional wear and abrasion resistance

- Available in black or natural

- Meets MIL-A-8625 Type III

Bright Dip Anodizing

- Pre-treatment for decorative applications

- Automotive and consumer products

- Creates highly polished surface

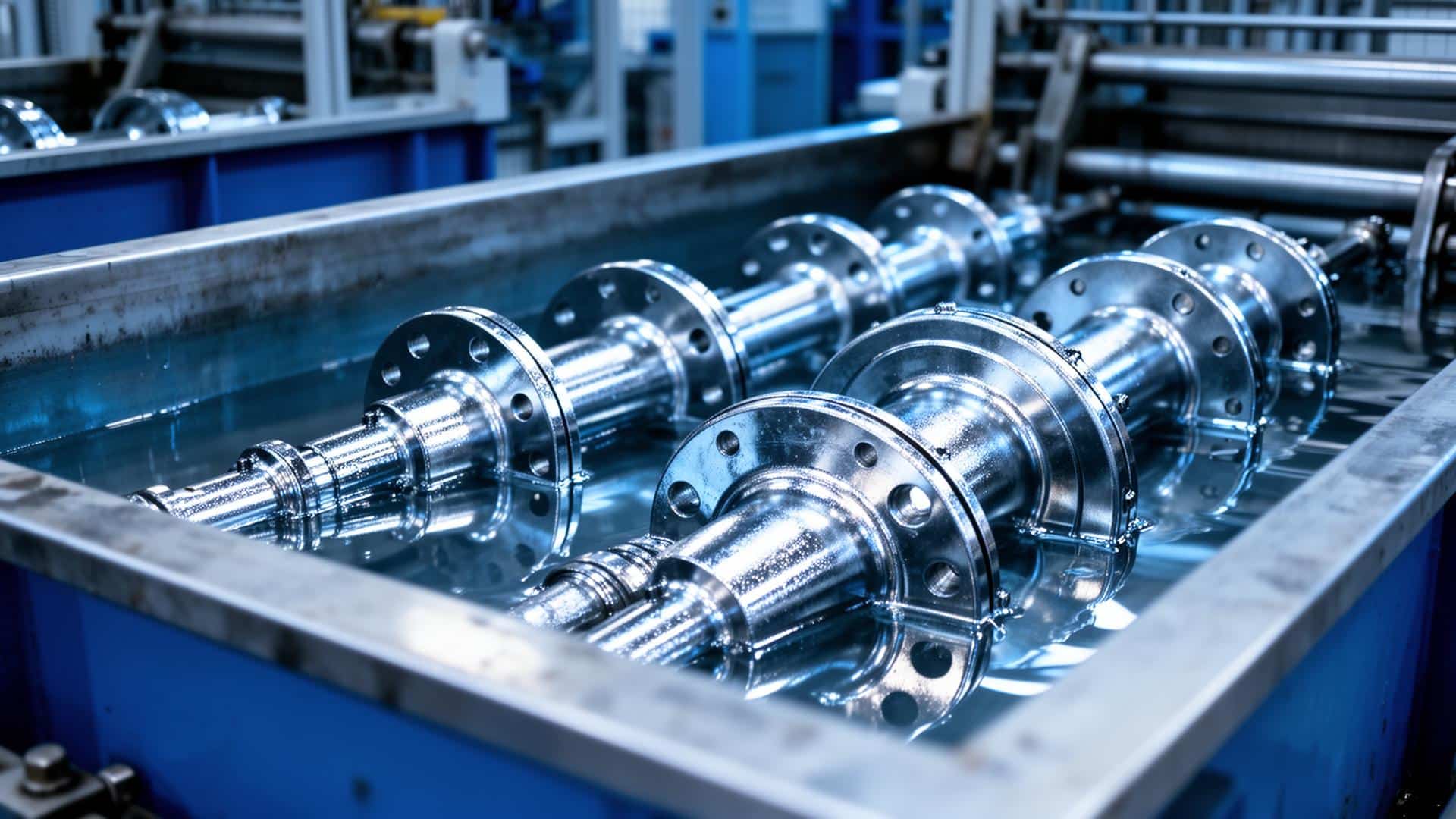

Electroplating Solutions.

Cadmium Plating

Superior corrosion protection, aerospace/military standard, excellent sacrificial protection

Zinc & Zinc-Nickel Plating

Cost-effective corrosion resistance, RoHS-compliant alternative to cadmium

Electroless Nickel Plating

Uniform coating on complex geometries, excellent wear and corrosion resistance

Copper Plating

Excellent electrical conductivity, undercoat for other platings, heat dissipation

Tin & Silver Plating

Food-grade safe finishes, excellent solderability, electrical applications

Chrome Plating (Decorative & Hard)

Decorative mirror-like appearance or extreme wear resistance for industrial use

Protective & Decorative Coatings

From powder coating to e-coating and chemical film treatments, we coordinate all your coating needs through certified partner facilities with documented quality systems.

Powder Coating

Dry powder finish electrostatically applied and heat-cured for durable, attractive coating.

- Thick, durable finish

- Wide color selection (RAL, Pantone)

- Environmentally friendly (no VOCs)

- UV resistant

E-Coating (Electrocoating)

Electrodeposition of paint for uniform, corrosion-resistant finish on complex geometries.

- Exceptional coverage on complex parts

- Superior corrosion protection

- Automotive-grade durability

Chemical Film (Alodine/Chromate)

Thin chemical conversion coating for aluminum providing corrosion resistance and paint adhesion.

- Exceptional wear and abrasion resistance

- Exceptional wear and abrasion resistance

- Available in black or natural

- Meets MIL-A-8625 Type III

Black Oxide

Chemical conversion coating for steel providing mild corrosion resistance and aesthetic black finish.

- Minimal dimensional change

- Improves lubricity with oil

- Cost-effective