Metal Fabrication Services.

Complete Surface Finishing Solutions

ISO 9001:2015

AWS Certified

2-4 weeks

Laser/Waterjet

Custom Metal Fabrication

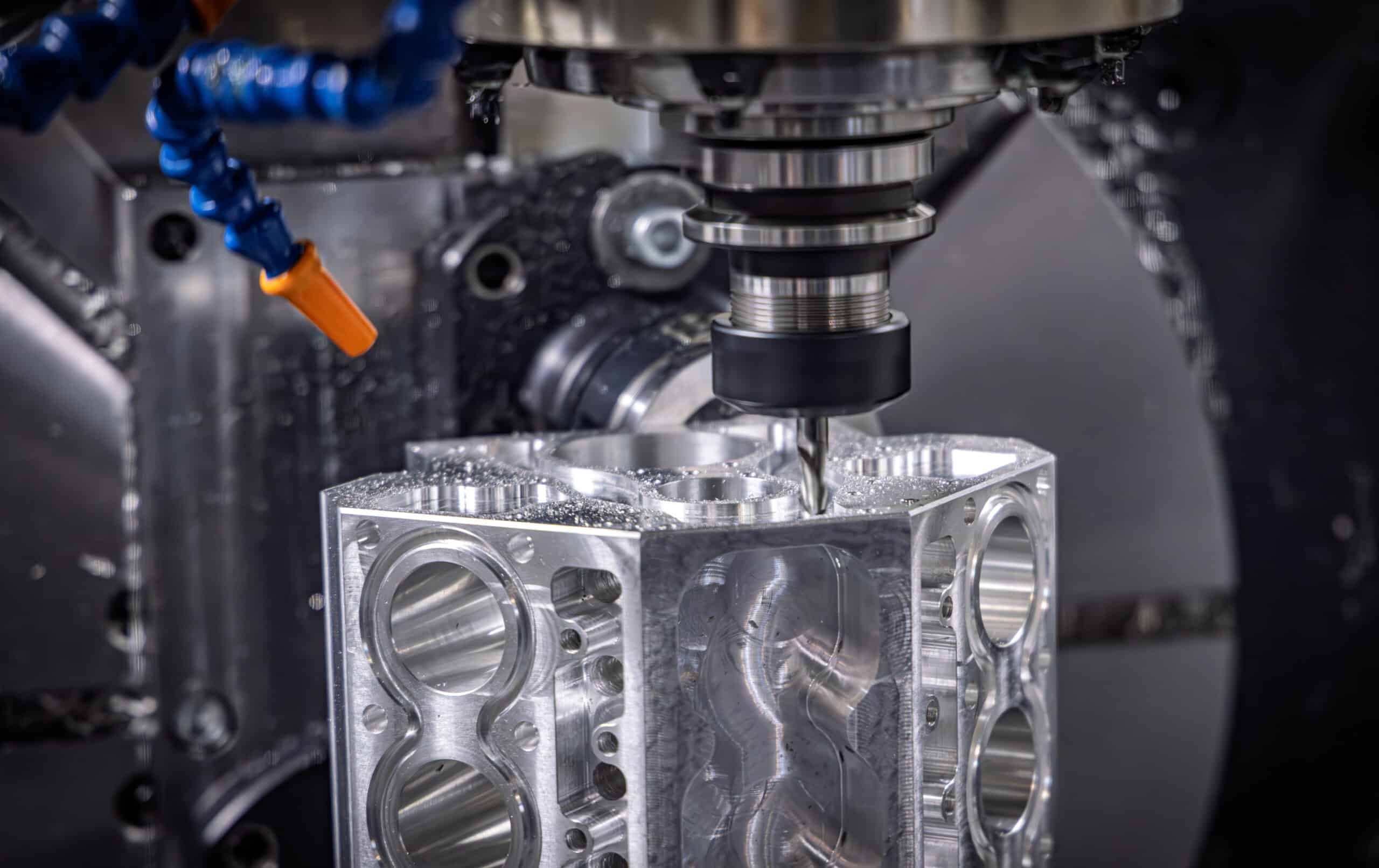

Metal fabrication transforms raw sheet metal, plate, and structural materials into finished components and assemblies. Our partner facilities combine advanced equipment with skilled craftsmen to deliver everything from simple brackets to complex welded assemblies.

Aerospace Metals coordinates fabrication, welding, finishing, and assembly—delivering complete, ready-to-install components.

Whether you need a single prototype or production quantities, Aerospace Metals coordinates with specialized machine shops to deliver exactly what you need—on time and to specification.

- Cutting & forming

- Finishing coordination

- Welding & assembly

- Complete documentation

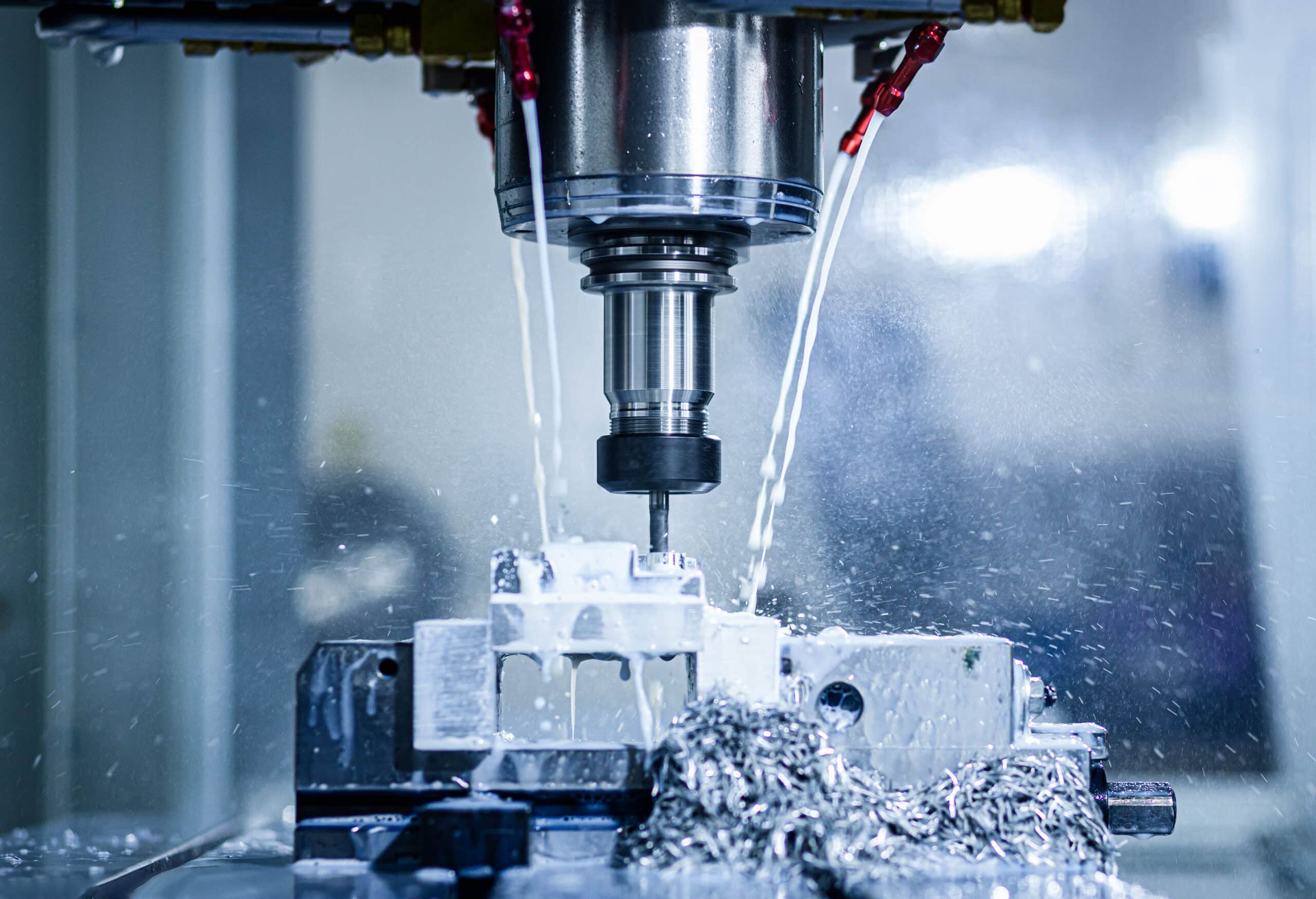

Cutting

- Laser cutting (CO2 and fiber lasers)

- Waterjet cutting (no heat-affected zone)

- Plasma cutting (thick materials)

- Turret punch presses (high-volume holes)

- Shearing (straight cuts)

Forming

- Press brake bending (up to 500 tons)

- Roll forming (cylinders, cones)

- Stamping and deep drawing

- Hydroforming (complex shapes)

Cutting

- Aluminum (various alloys), Stainless steel (304, 316, etc.), Carbon steel (cold/hot rolled), Galvanized steel, Copper, brass, bronze

Thickness Range

- 22 gauge to 1/2" plate (material dependent), Tolerances to ±0.005"

Welding Services.

MIG Welding (GMAW)

- High-speed production welding, excellent for aluminum and steel, automated/robotic available

TIG Welding (GTAW)

- Precision welding for critical applications, aerospace and medical quality, minimal distortion

Spot Welding

- Fast joining of sheet metal, automotive and appliance assemblies, consistent repeatable welds

Stick Welding (SMAW)

- Structural steel, thick materials, field welding capability

Welding Certifications Available

- AWS D1.1 (structural steel)

- AWS D1.2 (aluminum structures)

- AWS D17.1 (aerospace fusion welding)

- ASME Section IX (pressure vessels)

Common Fabrication Projects

Equipment Enclosures

- Electronics housings

- Control panels

- Server racks

- Outdoor cabinets

Structural Components

- Machine frames

- Equipment bases

- Support brackets

- Mounting plates

Custom Assemblies

- Multi-part welded assemblies

- Electro-mechanical integration

- Powder-coated assemblies

Ready to Order Materials? .

FAQs

What materials do you keep in stock?

What welding certifications do your partners hold?

Can Aerospace Metals fabricate custom enclosures?

Do you offer laser cutting and waterjet cutting?

Yes, we offer both. Laser cutting is ideal for high-speed precision on thinner sheet metal, while waterjet is used for thicker materials or heat-sensitive alloys. Aerospace Metals will select the best cutting method based on your material, thickness, and tolerance needs.

Can you handle large structural weldments?

What is your typical tolerance for sheet metal fabrication?

Can Aerospace Metals install hardware during fabrication?

Yes. We provide full hardware insertion services, including pressing in PEM nuts, studs, standoffs, and fasteners. Installing hardware during the fabrication stage ensures consistency and saves you significant assembly time on your production floor.