Laser Cutting .

- Quick Specifications

Lead Time

3-7 business days

Certifications

ISO 9001

Compatible Materials

Steel, Stainless Steel, Aluminum, Brass, Copper, Titanium

Industries

Aerospace, Medical, Electronics, Industrial Equipment, Automotive

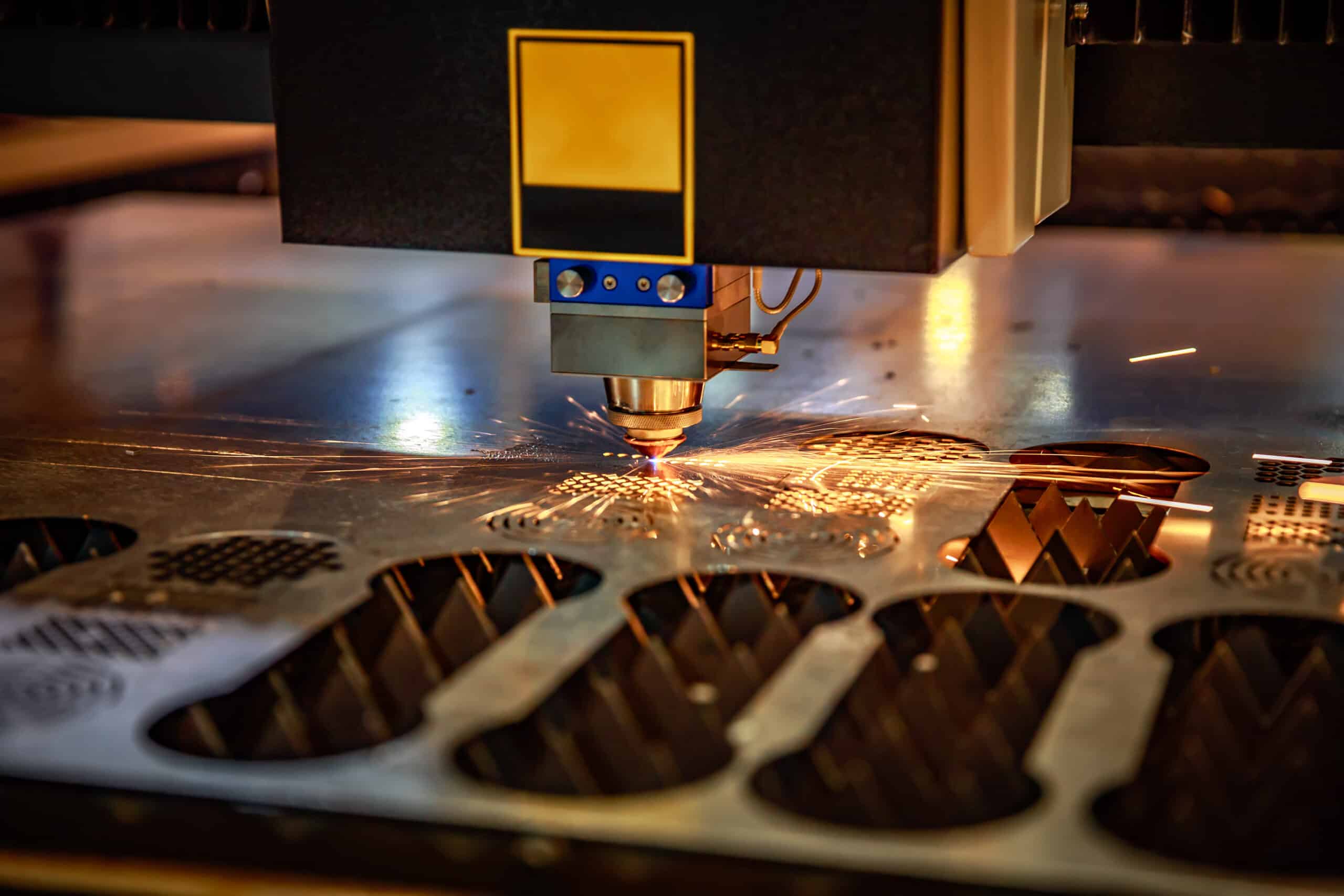

Laser Cutting

Fiber and CO2 laser cutting provides exceptional precision for cutting complex shapes in sheet metal with minimal heat-affected zones. The process delivers clean edges requiring little to no secondary finishing and maintains tight tolerances across large production runs.

Our network includes high-power fiber lasers capable of cutting thick materials with speed and precision. Laser cutting is ideal for prototypes through high-volume production.

- Precision cutting

- Complex shapes

- Minimal HAZ

- Clean edges

How Laser Cutting Works.

File Preparation

Your DXF/DWG files are optimized for cutting. Nesting maximizes material utilization.

Material Setup

Material loaded, settings optimized for your specific material type and thickness.

Laser Cutting

High-precision fiber or CO2 laser cutting with minimal heat-affected zone.

Deburring

Edge finishing removes any minor burrs for clean, ready-to-use parts.

Quality Check

Dimensional verification against your specifications before packaging.

Laser Cutting Solutions Across Industries

Aerospace & Aviation

Industrial Equipment

Medical Services

Automotive

Electronics

Available Certifications Across Network

ISO 9001:2015

AS9100 Rev D

Technical Specifications

Compatible Materials

Aluminum

Titanium

Brass

Stainless Steel

Steel

Copper

Available Processes

Fiber Laser

CO2 Laser

Tube Laser

Flat Sheet