our services

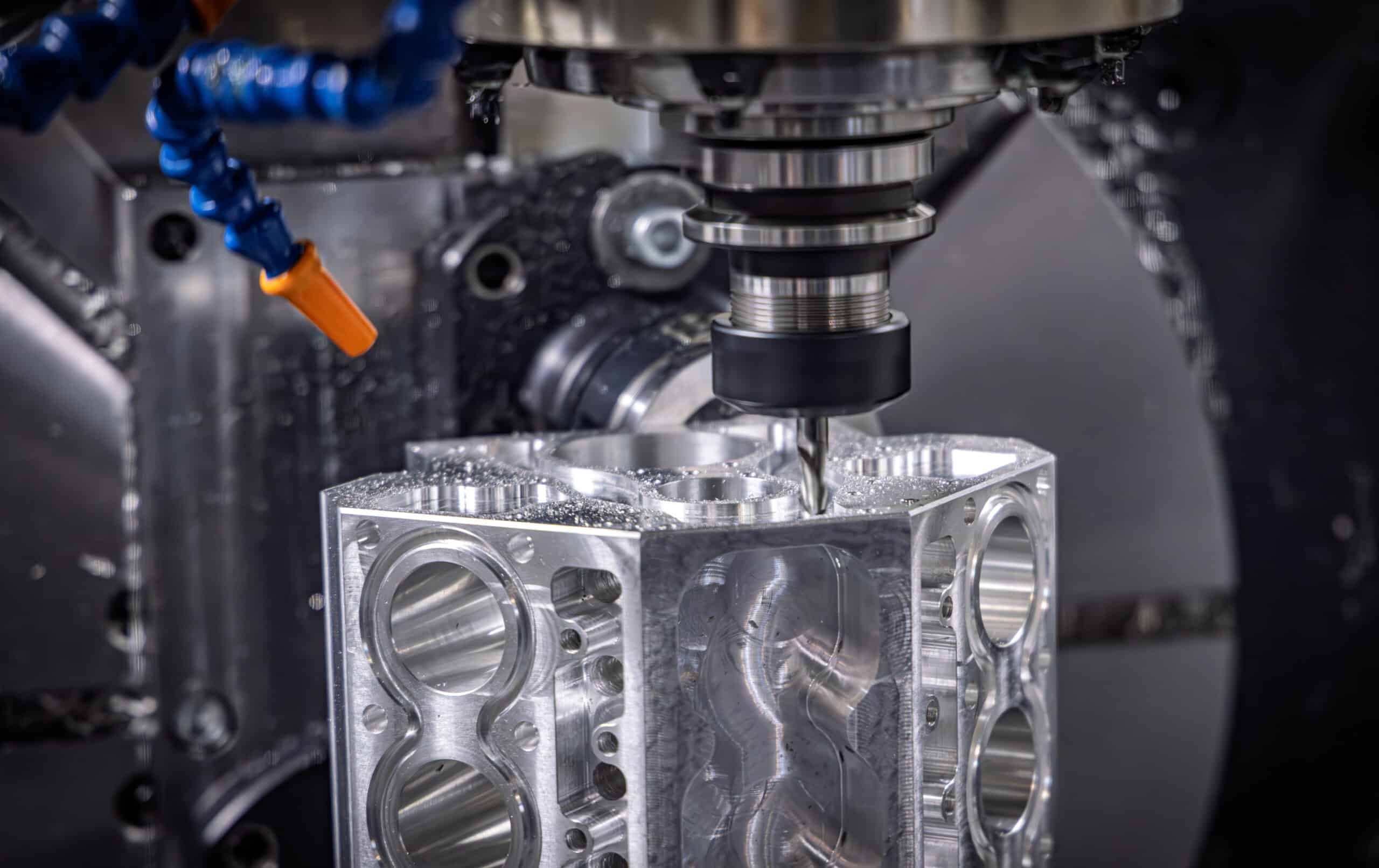

CNC Machining Services.

Prototype to production machining through our network of state-of-the-art facilities

Complete Surface Finishing Solutions

Metal finishing transforms functional components into high-performance parts. The right finish provides corrosion resistance, wear protection, electrical properties, aesthetic appeal, or specialized characteristics your application demands.

Certified Quality

ISO 9001 All Partners Certified

±0.0005"

Precision tolerances

2-3 weeks

Standard turnaround

3-5 Axis

Multi-axis capability

What is CNC Machining?

Precision Manufacturing Excellence

CNC (Computer Numerical Control) machining creates precision components from metal, plastic, and composite materials. Our partner facilities feature advanced multi-axis equipment and experienced machinists who deliver tight-tolerance parts consistently.

Whether you need a single prototype or production quantities, Aerospace Metals coordinates with specialized machine shops to deliver exactly what you need—on time and to specification.

- Prototype to production

- Wide material selection

- Multi-axis capability

- Full inspection reports

CNC Milling (3, 4, and 5-Axis)

- Complex 3D contours and surfaces

- Pockets, slots, holes, threads

- Precision tolerances to ±0.0005"

- Parts up to 60" x 40" x 30"

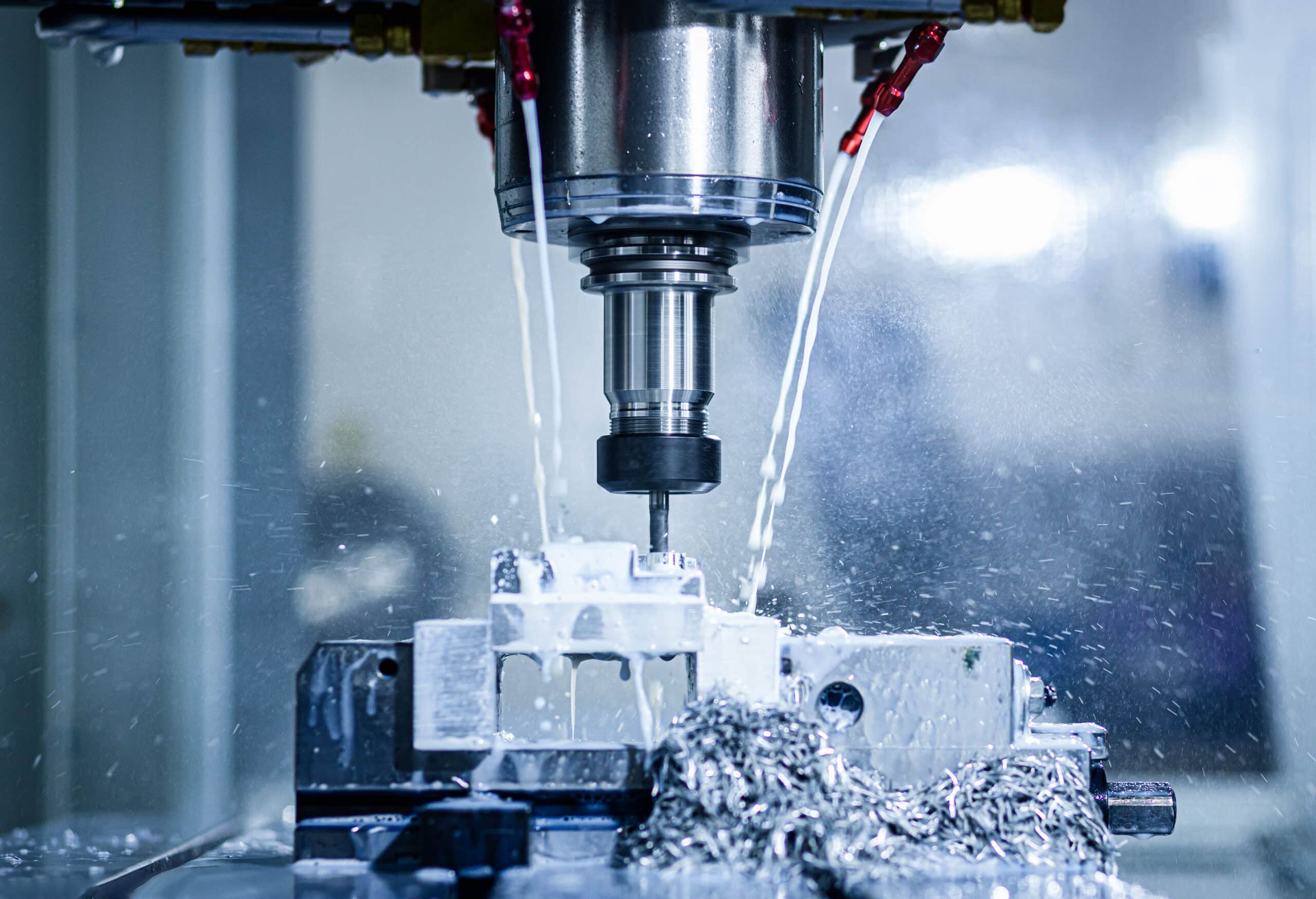

CNC Turning (Lathes)

- Shafts, pins, bushings, fittings

- Precision OD/ID tolerances

- Threading (internal/external)

- Diameters from 0.125" to 24"

Materials

Materials We Machine.

Aluminum Alloys

- 6061-T6 (general purpose)

- 7075-T6 (aerospace, high strength)

- 2024-T3 (aerospace, fatigue resistance)

- MIC-6 (precision tooling plate)

Stainless Steel

- 303 (best machinability)

- 304/304L (corrosion resistant)

- 316/316L (marine, chemical)

- 17-4 PH (high strength)

Titanium

- Grade 2 (commercially pure)

- Grade 5 (Ti-6Al-4V, aerospace)

Steel

- 1018 (mild steel)

- 4140/4340 (alloy steel)

- Tool steels (A2, D2, O1)

Other Metals

- Brass (free-cutting)

- Copper (electrical, thermal)

- Bronze (wear resistance)

Plastics

- Delrin/Acetal

- PEEK (medical)

- UHMW

- Nylon, polycarbonate

Scalability

Prototype to Production

From initial design validation to high-volume manufacturing, our scalable machining services provide a seamless transition through every stage of your product’s lifecycle.

Prototype Development

1-25 pieces

- Fast turnaround (1-2 weeks)

- Design feedback

- Cost optimization for production

Bridge Production

25-500 pieces

- Proven toolpaths

- Fixture design

- Statistical process control

Full Production

500+ pieces

- Dedicated production cells

- Just-in-time delivery

- Long-term pricing agreements

Ready to Order Materials? .

Request a material quote in 24 hours. Specify alloy, dimensions, quantity, and any processing needs.

FAQs

What tolerances can Aerospace Metals achieve?

Our partner network utilizes state-of-the-art multi-axis CNC equipment capable of holding tight tolerances down to ±0.0005 inches (or tighter upon review). Aerospace Metals routinely manages complex aerospace and medical components that demand exceptional precision.

Can you handle both prototype and production machining?

Yes. Aerospace Metals is set up to manage the entire product lifecycle. We have partners specializing in rapid prototyping (1-25 pieces) for design validation, as well as facilities dedicated to high-volume production (500+ pieces) with automated cells for maximum cost efficiency.

What file formats do you accept for quoting?

Aerospace Metals accepts most standard CAD file formats, including STEP (.stp), IGES (.igs), Parasolid (.x_t), and SolidWorks (.sldprt). For the most accurate quote, please also provide a 2D PDF drawing with critical dimensions, tolerances, and threads clearly marked.

Do you machine difficult or exotic materials?

Yes. While we machine standard aluminum and steel daily, Aerospace Metals has extensive experience with difficult-to-machine materials including Titanium (Grade 5, 23), Inconel, Monel, Hastelloy, and hardened tool steels, as well as engineering plastics like PEEK and Ultem.

Can Aerospace Metals provide inspection reports?

Absolutely. Quality documentation is a standard part of our service. Aerospace Metals can provide First Article Inspection (FAI) reports, AS9102 forms, material certifications (MTRs), and Certificate of Conformance (CoC) packages upon request.

How does your "single source" model benefit my project?

Most machined parts require secondary operations like anodizing or heat treating. Instead of you shipping parts between multiple vendors—risking damage and delays—Aerospace Metals handles the entire supply chain. We deliver a finished, plated, and inspected part to your dock.

What is the typical lead time for CNC machined parts?

Standard lead times are typically 2-3 weeks, depending on complexity and material availability. Aerospace Metals also offers expedited "bridge production" and rapid prototyping services for urgent deadlines.

Do you offer design assistance for manufacturability (DFM)?

Yes. The engineering team at Aerospace Metals has decades of machining experience. If we identify features that unnecessarily drive up cost or risk, we will provide DFM feedback to optimize your design for manufacturing, saving you money without compromising function.

Ready to Experience the Aerospace Metals Difference?