Hardcoat Anodizing Services (Type III).

- Quick Specifications

Lead Time

10-14 days

Materials

6061, 7075+

Certifications

ISO 9001, Nadcap

Industries

Aerospace, Defense

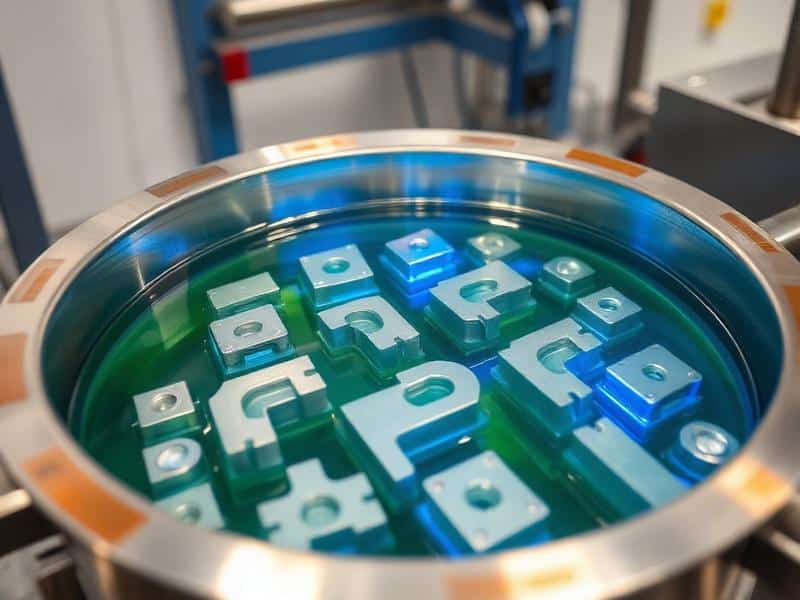

Type III Hard Anodizing

Hardcoat anodizing, also known as Type III anodizing or hard anodizing, is an electrochemical process that creates a thick, dense aluminum oxide layer on aluminum substrates. This coating provides exceptional hardness, wear resistance, and corrosion protection—significantly superior to standard Type II anodizing.

Hardcoat anodizing builds a coating typically 0.0008″ to 0.004″ thick (2-4x thicker than standard anodizing) with surface hardness approaching that of sapphire (typically 60-70 HRC on the Rockwell C scale).

Unlike coatings that can chip or peel, the anodic layer is integral to the aluminum substrate—it cannot separate because it IS the aluminum surface, converted to aluminum oxide.

60-70

HRC Hardness

2-4x

Thicker Coating

1000+

Hours Salt Spray

The Hardcoat Anodizing Process .

Total Process Time: 6-8 Hours

Part Preparation & Cleaning

Parts are thoroughly degreased and cleaned to remove oils, contaminants, and surface imperfections. Pre-anodizing inspection ensures parts are suitable.

Masking (If Required)

Critical dimensions, threads, or sealing surfaces may be masked to prevent anodic coating buildup using aluminum tape or specialty masking compounds.

Alkaline Etch (Optional)

Some alloys benefit from alkaline etching to remove surface oxides and create uniform surface texture for improved coating uniformity.

Desmut/Desmutting

Acid treatment removes surface smut and prepares aluminum surface for anodizing, ensuring clean, uniform surface for optimal coating.

Hardcoat Anodizing

Parts immersed in sulfuric acid electrolyte at 32-50°F. Electrical current converts aluminum surface to aluminum oxide (Al₂O₃). Process time: 45-90 minutes.

Dyeing (Optional)

If colored hardcoat is specified, parts are immersed in dye solution. Common colors: black, gray, gold, olive drab (military green).

Sealing

Hot water or nickel acetate sealing closes the porous anodic structure, enhancing corrosion resistance and locking in dye.

Final Inspection

Coating thickness measurement, visual inspection, and dimensional verification ensure parts meet specifications.

Benefits of Hardcoat Anodizing

Exceptional Wear Resistance

Surface hardness of 60-70 HRC resists abrasion, galling, and sliding wear. Ideal for moving parts and high-friction applications.

Superior Corrosion Protection

Dense aluminum oxide layer provides excellent barrier against salt spray, chemicals, and extreme weather conditions.

Electrical Insulation

Non-conductive coating provides insulation with breakdown voltage typically 400-600 volts per mil of coating.

Dimensional Stability

Coating grows 50% inward/outward from original surface. Predictable and repeatable for precision applications.

Heat Dissipation

Excellent thermal emissivity makes it effective for heat dissipation in electronics and high-temperature applications.

Integral Coating

Cannot peel, chip, or separate from substrate because it IS the converted aluminum surface. Permanent protection.

Dyeable Options

Can be dyed for identification, camouflage, or aesthetics. Colors typically darker/muted compared to Type II.

Environmentally Stable

Resistant to UV degradation, weathering, and environmental exposure. Does not fade or break down over time.

Hardcoat Anodizing Solutions Across Industries

Aerospace & Aviation

- Landing gear components

- Hydraulic cylinders and actuators

- Aircraft fasteners and fittings

- Structural components

- Helicopter rotor hubs

Defense & Military & Military

- Small arms components

- Military vehicle parts

- Optical equipment housings

- Communication enclosures

- Field equipment

Automotive

- High-performance pistons

- Engine components

- Suspension parts

- Racing components

- Heat management parts

Industrial Equipment

- Pistons and cylinders

- Pump components

- Conveyor system parts

- Textile machinery

- Semiconductor equipment

Technical Specifications

Compatible Materials

6061

Excellent results, widely used

7075

Excellent hardness

2024

Good results, aerospace

5052

Excellent corrosion resistance

7050, 7175

Aerospace grades

MIC-6, ATP5

Tooling plate

Alloys with high silicon content (casting alloys) produce softer, less uniform coatings.

Mil-Spec Compliance

MIL-A-8625 Type III, Class 1

Clear/natural, sealed

MIL-A-8625 Type III, Class 2

Dyed, sealed

AMS 2469

Hardcoat Anodizing of Aluminum Alloys

Coating Thickness

Light Hardcoat

20-38 microns

0.0008" - 0.0015"

Standard Hardcoat

38-64 microns

0.0015" - 0.0025"

Heavy Hardcoat

64-102 microns

0.0025" - 0.004"

Compatible Materials

Natural/Clear

Black

Gray

Gold/Bronze

#4A5C3B

Custom Colors

Surface Hardness

Tolerance Considerations

How Hardcoat Compares

| Feature | Hardcoat (Type III) | Standard Type II | Bright Dip | Hard Chrome |

|---|---|---|---|---|

| Coating Thickness | 0.0008"-0.004" | 0.0002"-0.001" | 0.0001"-0.0003" | 0.0005"-0.010" |

| Surface Hardness | 60-70 HRC | 40-50 HRC | 40-50 HRC | 65-70 HRC |

| Wear Resistance | ✔ Excellent | – Moderate | – Moderate | ✔ Excellent |

| Corrosion Resistance | ✔ Excellent | ✔ Excellent | ✔ Excellent | ✔ Excellent |

| Electrical Insulation | ✔ Excellent | – Good | – Good | ✖ None |

| Finish Appearance | Matte gray/dark | Semi-gloss | Mirror | Bright |

| Cost | $$$ | $ | $$ | $$$$ |

| Lead Time | 10-14 days | 5-7 days | 7-10 days | 14-21 days |

| Best For | Wear + corrosion | General protection | Aesthetics | Wear (steel) |

Quality You Can Trust

ISO 9001:2015

AS9100 Rev D

Nadcap

MIL-A-8625

- Documentation Provided

- Certificate of Conformance

- Process certifications

- Salt spray test reports

- Material certifications

- Thickness measurements

- Photographic documentation

Why Choose Aerospace Metals.

Nadcap-Accredited Partners

For aerospace and defense applications, we work exclusively with Nadcap-accredited facilities meeting the most demanding industry standards.

33 Years of Expertise

Paul Fredericks has coordinated thousands of hardcoat anodizing projects. He knows which facilities excel at specific component types.

Engineering Support

Not sure if hardcoat is right? We'll review your requirements and recommend the optimal surface treatment.

Multi-Process Projects

Machining before anodizing? Masking? Post-anodize machining? We coordinate all processes seamlessly as a single project.

Fast Turnaround

Network capacity for urgent projects without compromising quality. Rush service available for AOG and critical situations.

Complete Documentation

Full traceability packages including process logs, thickness measurements, test reports, and First Article Inspection when required.