About Aerospace Metals: 33 Years of Metal Finishing Excellence.

How We Started

Aerospace Metals was formed as a subsidiary of an aluminum anodizing company in 2012.

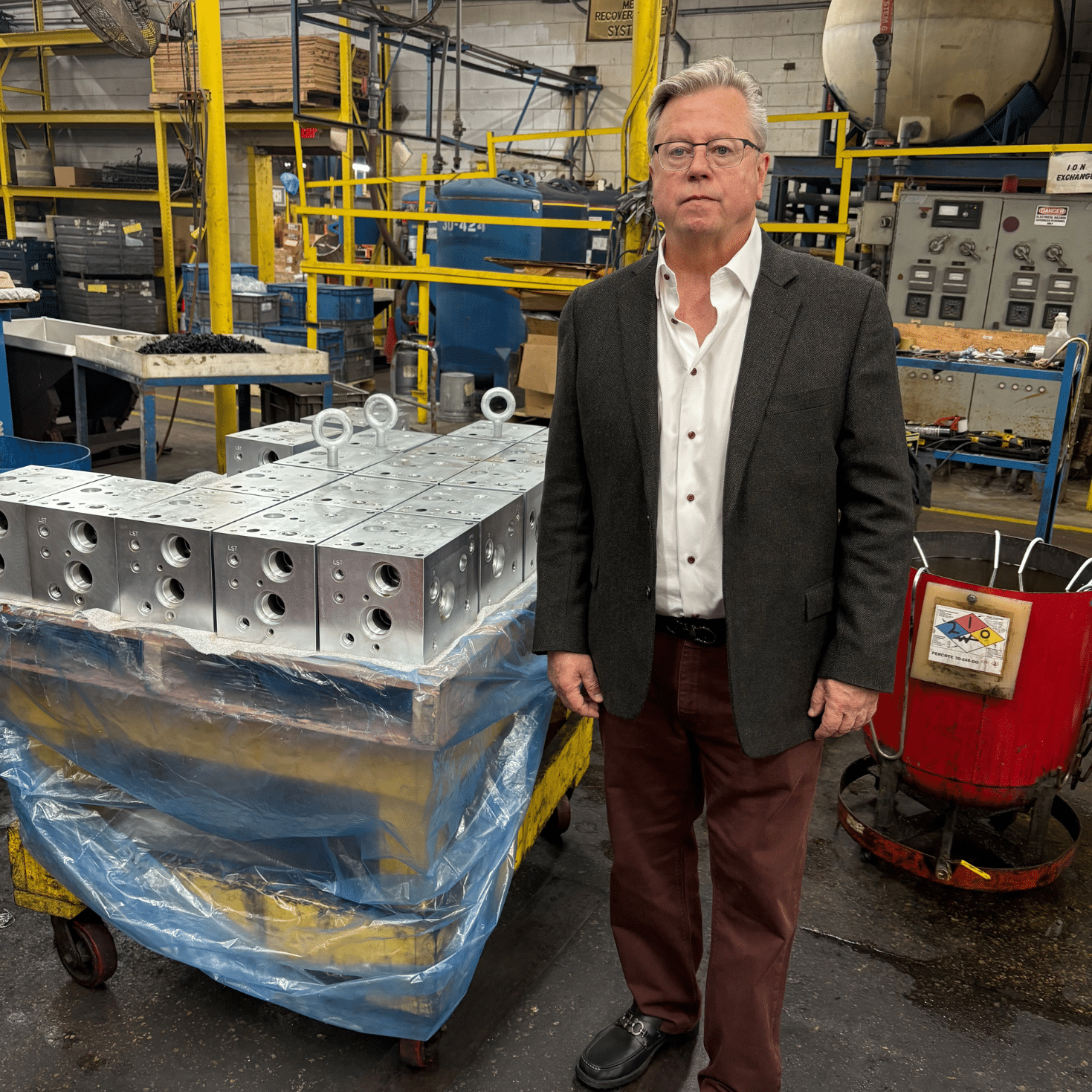

Paul Fredericks has owned and operated four metal finishing companies since 1987. During this time, he recognized from his O.E.M. customers that it was difficult to find an efficient outsourcing system to send out parts for Fabrication, CNC Machining, and Finishing.

Days if not weeks were spent sending out RFQ’s, exchanging drawings, not understanding drawings, misunderstanding alloys, receiving no quotes, inconsistent pricing and unacceptable lead times.

- The Problem We Solved

- Sending RFQs to multiple shops with inconsistent responses

- Struggling to communicate technical requirements

- Dealing with material specification confusion

- Receiving wildly varying quotes (or no quotes at all)

- Waiting weeks for basic turnaround times

- Managing multiple vendors for multi-process projects

- Our Solution

Aerospace Metals was created to solve these exact problems. Instead of maintaining our own facility with limited capabilities, we built a vetted network of the best metal finishing, machining, and fabrication partners across North America.

This model gives our customers single point of contact, access to specialized equipment, consistent quality, faster turnaround, competitive pricing, and backup capacity.

How We Started

Paul J. Fredericks

Owner & President

Paul has owned and operated four metal finishing companies since 1987, giving him unparalleled insight into what separates exceptional finishing from merely acceptable work.

Anna Otto

VP Sales

Anna expanded our reach to serve manufacturers nationally and internationally. She manages logistics, coordinates international shipments, and ensures seamless communication.

50+ Certified Facilities Across North America .

Best Partner Every Time

We select the perfect certified facility for each specific project

Unlimited Scalability

Network scales up or down without capacity constraints

Geographic Flexibility

50+ partners across North America for optimized logistics

Single Point of Contact

One relationship, one invoice, complete coordination

- All Partners Maintain

- ISO 9001:2015 certification (minimum)

- Regular auditing and compliance verification

- Documented quality management systems

- Proven track record of on-time delivery

Available Certifications Across Network

ISO 9001:2015

AS9100 Rev D

Nadcap

ITAR Registered

ISO 13485

PPAP Capable

Simple, Streamlined Process

Expertise First

Quality Obsession

Speed & Reliability

Transparency

Partnership Mindset

What Our Customers Say

Do you own your own metal finishing facilities?

No, and that's actually your advantage. As a non-asset broker, we aren't limited to one facility's capabilities, capacity, or geographic location. We've built relationships with 50+ certified facilities across North America, which allows us to select the perfect partner for each specific project based on your requirements, timeline, and location.

How do you ensure consistent quality across different facilities?

Every facility in our network must meet strict qualification criteria: ISO 9001:2015 certification minimum, proven quality track record, state-of-the-art equipment, and excellent customer service standards. Paul Fredericks personally vets each facility.

Who will I be working with on my project?

You'll work directly with Aerospace Metals—Paul Fredericks and Anna Otto. We handle all communication, project coordination, and quality oversight. You'll never need to communicate with multiple vendors.

What if a facility has quality issues with my parts?

We have backup partners for every process, and we immediately address any quality concerns. If an issue does occur, we take full responsibility and work with the facility (or move to a backup partner) to make it right.

Where are you located?

Our operations are based in Los Angeles. However, our partner network spans 50+ facilities across the United States, Canada, and Mexico.

What industries do you primarily serve?

Aerospace & aviation, defense & military, medical devices, electronics, automotive, industrial equipment, food & beverage, and energy.

Can you handle both prototype and production runs?

Yes, absolutely. Our network includes facilities equipped for everything from single prototype parts to high-volume production runs.