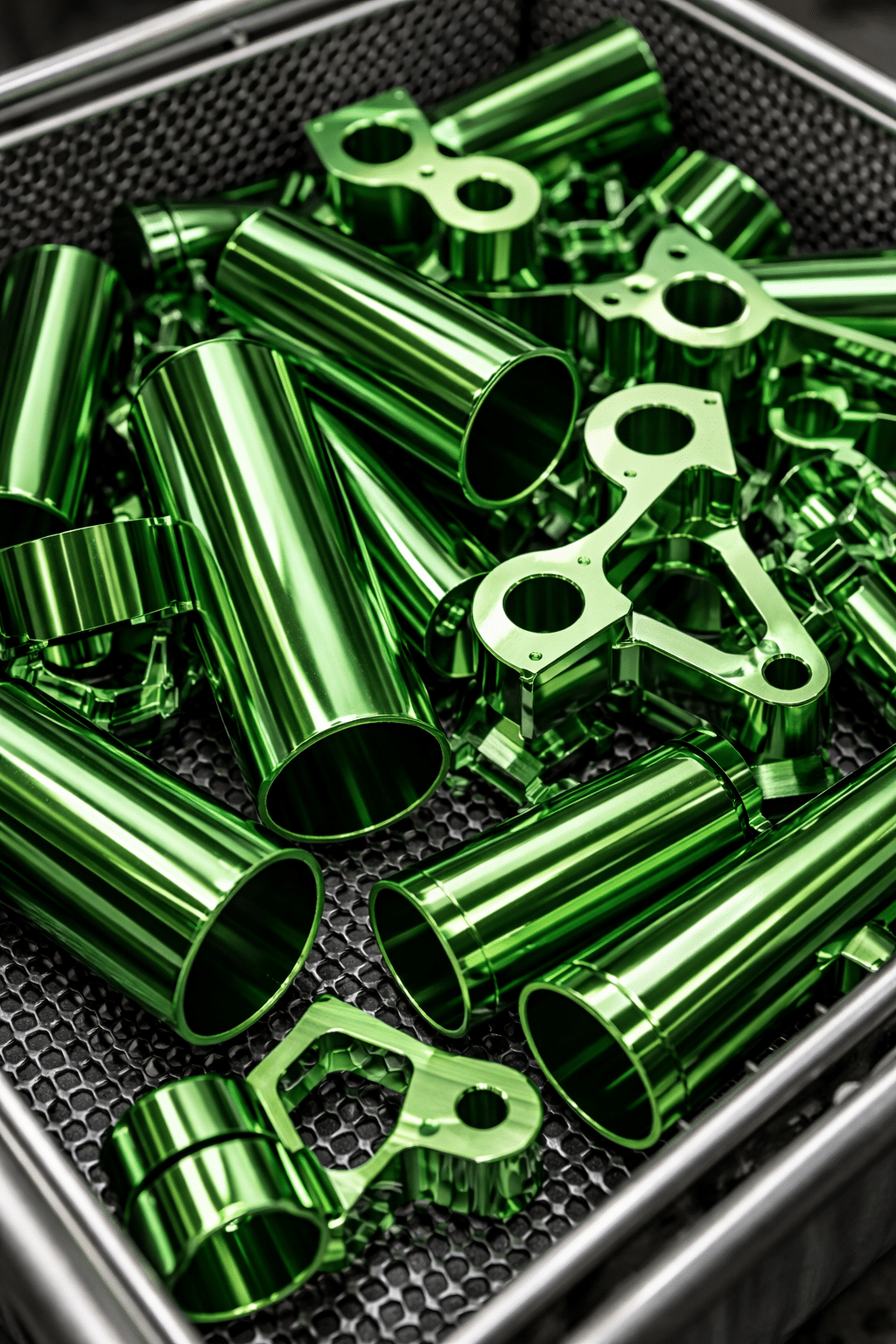

Bright dip anodizing is a specialized aluminum finishing process designed to achieve high surface reflectivity, enhanced corrosion resistance, and long-term durability. Unlike conventional mechanical polishing or cosmetic coatings, bright dip anodizing relies on controlled chemical and electrochemical reactions to deliver a uniform, high-performance finish.

This process is widely used across industries where aluminum components must meet both visual and functional requirements.

What Is Bright Dip Anodizing?

Bright dip anodizing is a multi-step aluminum anodizing process that begins with chemical polishing. Aluminum parts are immersed in a heated phosphoric- and nitric-acid-based solution that selectively dissolves microscopic surface peaks. This controlled material removal smooths the surface at a microscopic level, producing a highly reflective, mirror-like finish.

After chemical polishing, the parts undergo anodization, an electrochemical process that converts the aluminum surface into a dense aluminum oxide layer. This oxide layer is integral to the base material, providing improved corrosion resistance, surface hardness, and wear performance without adding measurable thickness.

Technical Considerations in the Process

Achieving consistent results with bright dip anodizing requires strict control over several variables, including:

- Alloy composition (not all aluminum alloys respond equally)

- Bath chemistry and temperature

- Immersion time and current density during anodizing

- Surface preparation and cleanliness

Small variations in these parameters can affect brightness, uniformity, and oxide layer quality. Because the anodic layer grows inward and outward from the original surface, dimensional impact is minimal—making bright dip anodizing suitable for tight-tolerance components.

Performance Benefits

When properly executed, bright dip anodizing offers:

- High optical reflectivity

- Excellent corrosion resistance

- Improved surface hardness

- Uniform, repeatable surface quality

- No risk of peeling or delamination

These benefits make it a preferred aluminum surface finishing method for components exposed to demanding environments or frequent handling.

Industries That Utilize Bright Dip Anodizing

Bright dip anodizing is used across multiple industries, including:

- Automotive – decorative trim, interior accents, and functional components

- Consumer electronics – aluminum housings and visible structural parts

- Lighting and optics – reflectors and high-efficiency light components

- Architectural and design – fixtures, hardware, and decorative aluminum elements

- Industrial manufacturing – precision aluminum parts requiring durability and appearance

Precision You Can Trust

At Aerospace Metals, we understand that aluminum finishing is a critical extension of material performance—not just a cosmetic step. Our expertise in aluminum alloys and controlled finishing processes ensures consistent, high-quality results that meet exacting technical requirements across industries.

Whether your application demands reflectivity, corrosion protection, or dimensional stability, bright dip anodizing delivers a refined solution backed by precision processing.