TIG Welding.

- Quick Specifications

Lead Time

5-10 business days

Certifications

AWS D17.1

Compatible Materials

Stainless Steel, Aluminum, Titanium, Inconel, Carbon Steel, Copper Alloys

Industries

Aerospace, Medical, Food & Beverage, Energy, Defense

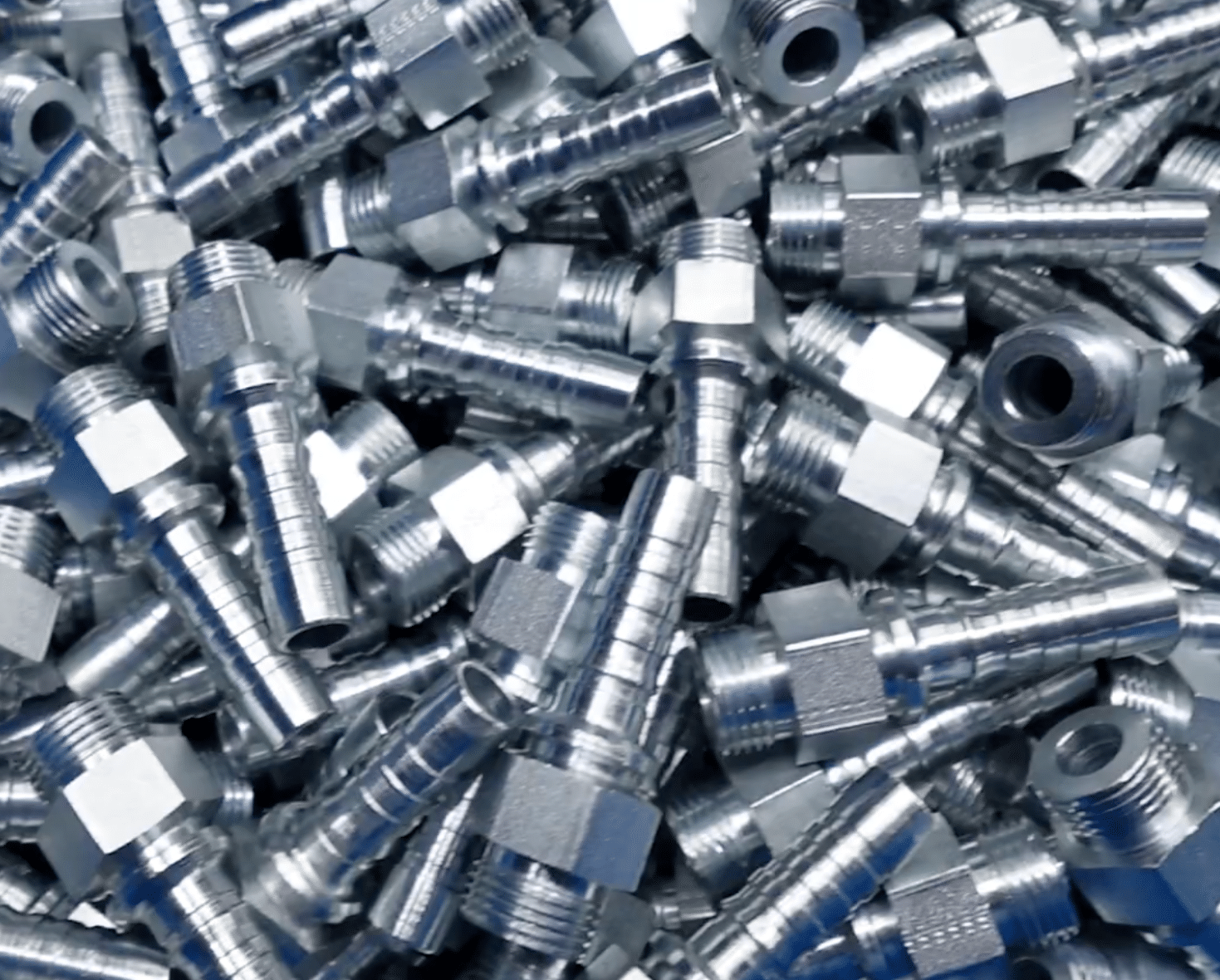

TIG Welding

TIG (GTAW) welding produces the highest quality welds with excellent control over heat input and filler metal deposition. The process is essential for aerospace, medical, and food-grade applications where weld quality, appearance, and material integrity are critical.

Our certified welders hold qualifications for aerospace primes and meet AWS D17.1 and other demanding specifications. TIG welding is available for aluminum, stainless steel, titanium, and exotic alloys.

- Superior weld quality

- Precise control

- Excellent appearance

- All positions

How TIG Welding Works.

Weld Prep

Joint preparation, fit-up, and cleaning ensure optimal weld quality.

Procedure Review

Welding procedure specification (WPS) confirms parameters for your material and application.

TIG Welding

Certified welders execute precision TIG welds with controlled heat input.

Weld Inspection

Visual inspection, dye penetrant, or X-ray as specified for your application.

Post-Weld Finishing

Grinding, polishing, or passivation as required for final appearance.

TIG Welding Solutions Across Industries

Aerospace & Aviation

Food & Beverage

Medical Services

Energy

Defense

Available Certifications Across Network

AWS D17.1

AWS D1.1

ASME Section IX

Nadcap

ISO 9001

Technical Specifications

Compatible Materials

Aluminum

Titanium

Inconel

Stainless Steel

Carbon Steel

Copper Alloys

Available Processes

Manual TIG

Orbital Welding

Pulse TIG

Hot Wire TIG